Could undetected material weaknesses comprise your product quality? The answer is yes. Despite running multiple tests, or changing raw materials so many times, you fail to keep a record of it? Frustrating right? A burden on the pocket too? We understand your situation. To give you relief from all your worries, we have an ideal tool for you!

Let's understand the problem first!

It is quite understandable that the lack of rigorous testing might result in “increased deformity rates”. If the strength of the material remains unknown, it may result in overvaluation or undervaluation of strength. This makes it difficult for the manufacturers to figure out the exact strength of the material, and how to plan items that can withstand the various pressures in real life. Now let’s know about the answer to all these questions.

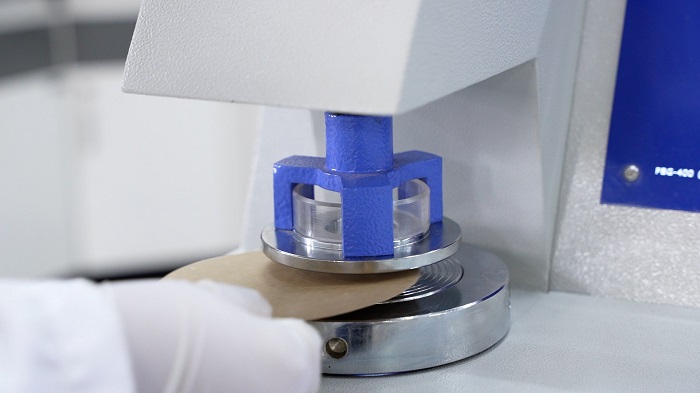

A Bursting strength tester is one of the most useful devices for manufacturers. This machine is designed for the purpose of checking the capacity, or to measure the ability, of a material to withstand the pressures of daily life. This machine is all about how much strength a material has, to not bow in front of the pressure. There are various materials that endure much pressure in day-to-day life. These materials are paper, corrugated sheets, mono-carton sheets, etc.

The main aim of this device is to check the pressure at which the sample bursts or ruptures.

Let’s dive a little deeper into why BURSTING STRENGTH TESTER is one of the hot-selling machines.

One of the unique features of this device is that two types of tests can be performed on this single machine, without the installation of any additional fixtures. These tests are:

The material is specified for both tests. Paper, mono-carton sheets, and corrugated sheets are used for sampling for BST, whereas, for BFT only paper and mono-cartons can be used, as samples.

| Display | • LED (Digital) • Graphical |

| Accuracy | ± 1% within 10% t o 90% of entire range as per IS: 1828 with master gauge |

| Least Count/Resolution | 0.1Kg/cm2 |

| Power | 220V, Single phase, 50 Hz |

| Test fluid | Glycerinabout 98% purified (lab grade) |

| Rate of fluid displacement | 95 cc/minute |

| Motor | 1/4 HP, Single Phase, 1440 rpm |

| Test Range | 1Kg/cm to 38 Kg/cm2 |

| Memory (to hold test value) | Up to 9 test values |

| Peak Hold Facility | Yes |

| Sample report with Graph | 10 sample tests report in just one report |

| Safety Switch | Yes |

| Material | Mild Steel |

| Finish | Powder coated Havel Gray & Blue combination finish and bright chrome / zinc plating for corrosion resistant finish |

| Dimensions | 540x 600x 450 mm |

| Communication port | RS 232 |

ANY MORE DOUBTS? CLEAR AWAY

Bursting strength of a material, gives insights about the durability, and quality of the material. This helps in direction, whether or not the material should be used for production.

The principle difference between the two is, bursting strength defines what amount of pressure can a material endure, from all directions. Whereas, the tensile strength defines, amount of force required to pull apart a material from a single direction.

The pressure is always applied by the machine from the bottom.

There are no specifications for the sample, although the manufacturers can use a sample of 10 by 10 cm.

It is quite simple to interpret the results. The material with higher value means that it is strong enough to endure a high amount of pressure. The material with lower value means that it is not fit for production, as it can not endure much pressure.

LET’S START TOGETHER.

We hope some of your doubts have been cleared by now. If there’s anything more that you need to know, contact us at +91 99210903903 or send your queries over mail at info@prestogroup.com

We’ll be happy to assist you!

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?