When packaging fails to maintain its integrity when put through real-life situations, it puts a burden on the manufacturers to adapt more protective measures and shift to other costly alternatives. This not only poses a threat to the pockets of the manufacturers but also ruptures their brand reputation. It becomes clear that ineffective packaging can severely impact cost efficiency and logistics in several ways.

Addressing issues like the high rate of product damage, product returns, bad customer reviews, loss of customer trust, and mainly extra costs incurred can prove to be much more expensive than investing in the proper packaging of the goods.

Moreover, without conducting a proper test for the packaging, the manufacturers may underestimate or overestimate the product’s strength to efficiently endure all the pressure that they are put to during the distribution process.

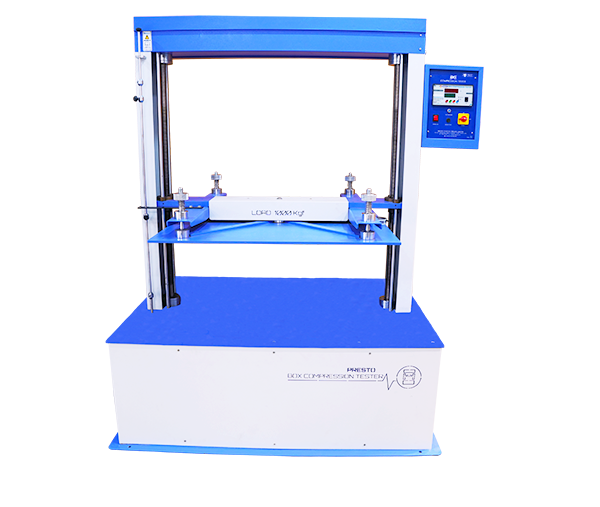

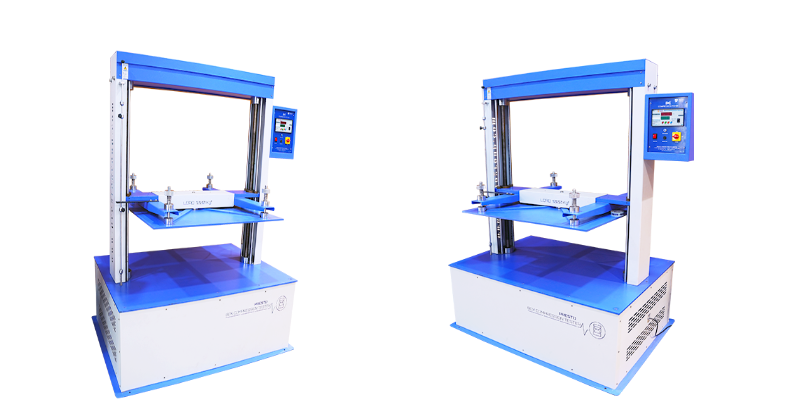

To relieve you from this stressful situation we have brought to you a BOX COMPRESSION TESTER.

To achieve all the objectives mentioned above, a box compression tester can be the perfect machine to be used. A box compression tester will allow you to check the stack load of your product, such as a corrugated box, mono carton box, etc. This will measure the maximum force that your product can withstand without getting deformed.

Conducting this test becomes essential to verify the durability, stability, and strength of the box. This ensures that the contents inside the box are effectively protected from any kind of pressure during processes like handling and shipping. Once it is understood how much pressure a box can handle, its design can be customized as per the requirements ensuring quality control.

In the packaging industry, commonly used materials are corrugated boxes and mono-carton boxes. Both are essential because of their unique features and are perfectly suitable for their intended functions.

There is a diverse range of options available when we talk about a box compression tester. Each one is different and designed with utmost efficiency and precision catering to the specific needs of the manufacturers of boxes. These models are different from each other in terms of features, size, and automation levels. Despite choosing any model, there’s one thing for sure—the results you will obtain will be perfectly accurate with no error, making them the ideal solutions for packaging evaluation.

Here’s the list of various types of models available:

The digital model is a user-friendly model which uses advanced electronic sensors and digital displays.

This model consists of a combination of a motorized mechanism and a software-integrated system. These features help in the precise application of force and software helps in advanced data analysis and reporting.

This model is completely automated. The Prima model is also software-driven along with many automation features. Moreover, this model provides printed results of the test conducted.

STEP 1: SAMPLE PREPARATION

Select the packaging material or box that is to be tested to ensure that it is in its intended form with all the closures and sealing in place.

STEP 2: ADJUST THE TESTER CALIBRATION:

Make sure that the box compression tester is calibrated according to the requirements to obtain precise results.

STEP 3: POSITION THE BOX:

Place the box properly on the machine’s platform, mainly between the compression plates, to make sure the box is properly aligned and centered.

STEP 4: COMMENCE WITH THE TEST:

Start the test. The tester will start applying force to the box with the compression plates at a controlled rate. Make sure the test runs smoothly and no issues arise with the sample or the equipment.

STEP 5: ANALYZE AND RECORD THE DATA:

Record the maximum amount of force at which the box started deforming. You can obtain the printed report if the model is automated.

What is the box compression tester's typical load capacity?

The load capacity range of the box compression tester typically begins at 100 kg, 500 kg, and 1000 kg. Nevertheless, it can be altered to meet the specifications of the manufacturer.

What kind of materials can be tested through the box compression tester?

Specifically, two types of materials can be tested through the box compression tester. The first one is a corrugated box and the second one is a monocarton box.

What is the maximum speed at which the machine can conduct tests?

The testing speed of the machine is 12.7 ± 2 mm/min, but the maximum speed this machine offers is 50 mm/min.

If there’s anything more you need to know, contact us at +919210903903 or send your queries over mail at info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?