All the products that are laid out by manufacturers undergo printing for either the marketing content or for sharing some necessary knowledge regarding the product being laid out. Printing plays a pivotal role in the lives of manufacturers as well as the end consumers.

For example, in the case of a perishable item, the expiry date along with the manufacturing date is printed on the backside as a warning for the consumer and also as per compliance with designated food & item standards.

This is the reason which makes the quality of printing an extremely important aspect even after the manufacturing of a product is completed. Correct printing eradicates the scope of misleading and faulty knowledge being spread across.

Presto Stantest Pvt Ltd. offers the ink abrasion resistance tester to curb the issue of testing the printing quality over materials to ensure long-lasting print and eradicate the scope of misleading.

The lab testing instrument is designed with top-class engineering to enhance the print quality of materials by evaluating the ability of the printed ink to withstand abrasion. These printings vanish due to abrasion after a point of time, therefore it is necessary to determine the abrasion resistance of printed materials.

Let us acknowledge the functioning mechanism of the ink rub tester that aids manufacturers in achieving highly accurate results consistently.

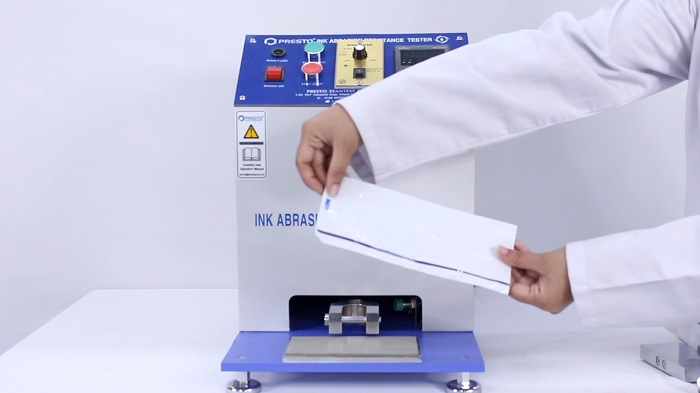

The ink abrasion resistance testing has been made very easy with the Presto designed printing ink abrasion tester as it offers an operator-friendly approach.

The instrument has dedicated specimen holders that allow manufacturers to place specimens on both fixtures and clamp them firmly to ensure zero slippage during the course of testing.

The instrument allows a sample-to-sample measurement of abrasive resistance to simulate the experiences that these samples undergo during transportation and other storage activities.

Once the operator makes sure that specimens are firmly clamped, it is now time to position the specimen over the motorized fixture.

After fixing the specimen, the operator can simply adjust the time of testing which can be as high as 9999 secs: hrs: mins. The operator can also adjust the rpm (rubs per minute) of the upper fixture rubbing against the specimen that is associated with the stationary lower fixture.

The instrument rubs in a motion that is similar to linear motion called the arc reciprocatory movement. This ensures accuracy and absolutely precise testing results over & over again.

The specimen being tested is forced under a pressure of 2 lbs – 4 lbs as per the requirement of the operator or the standard being considered.

After the completion of the preset timer’s time, the operators can simply determine the quality of printing just by looking at it and can make sure whether their quality is up to the mark or not.

There are certain features that the ink rub tester is loaded with, that enhance the overall quality of the instrument.

The printing ink abrasion tester is equipped with a microprocessor-based display that helps the operator record the results with absolute facile. The inclusion of a preset timer along with the display allows auto turn off of the instrument once testing is performed. This promotes hassle-free testing repeatedly and derives accurate results.

The instrument ensures that there is minimal or almost negligible sound while performing the test due to the smooth orientation of the machinery. This allows the lab testing instrument to quietly perform the test.

The distribution of the load that can differ from 2-4 lbs is even & uniform, ensuring an accuracy-driven approach over & over again.

The instrument is made up of mild steel material that is coated with 7-layered powder-coated paint to avoid any kind of rusting or corrosion when the instrument is exposed to the environment.

The adjustable rpm option enables the manufacturer to attain the results as per the personal requirement or as per the considered standard for checking the quality of printing.

All these top-quality features contribute towards hassle-free testing by the operator, eradicating the scope of human error by enhancing technical conditioning.

Some prevalent questions regarding the ink abrasion tester that often come across the mind of manufacturers are:

Presto Stantest Pvt. Ltd. offers an extremely worthy price for the ink resistance and scuff test instrument. To get your hands on the top-notch device, book an order right away by calling us at +91 9210903903 or write to us in order to seek any information or state your feedback via e-mail at info@prstogroup.com.

To seek more information regarding lab testing instruments, you can go through our website and enhance your knowledge. The Presto Group wishes to deliver the highest quality to each & every individual out there, which keeps us going and motivates us to deliver futuristic lab testing instruments to manufacturers from all across the industries. Be a part of the change with Presto.

Ans. The manufacturers work super hard in the production of every product, however, just a casual step of misprinting or poor-quality printing can put an end to the entire production process. This is the reason that the Presto Group has come with the Printing Ink Abrasion tester that ensures that the printing quality of the specimen can withstand abrasion as per compliance standards.

Ans. The testing of a specimen is conducted at a maximum speed of 43 cyclic rubs in an arc reciprocatory motion. However, the operator can adjust the timer or the number of rubs with the help of a preset timer.

Ans. The ink rub tester manufacturer in India provides an even & uniform pressure of 2 lbs to 4 lbs in order to ensure highly accurate test results.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?