Hey! Ever wondered what the muffle furnace leaves behind after it has completed its cycle? No, it's not just a pile of "dust bunnies," but actually, something a little more scientific by the name of ash content. Unravel this mystery and discover why this innocuous residue holds such value.

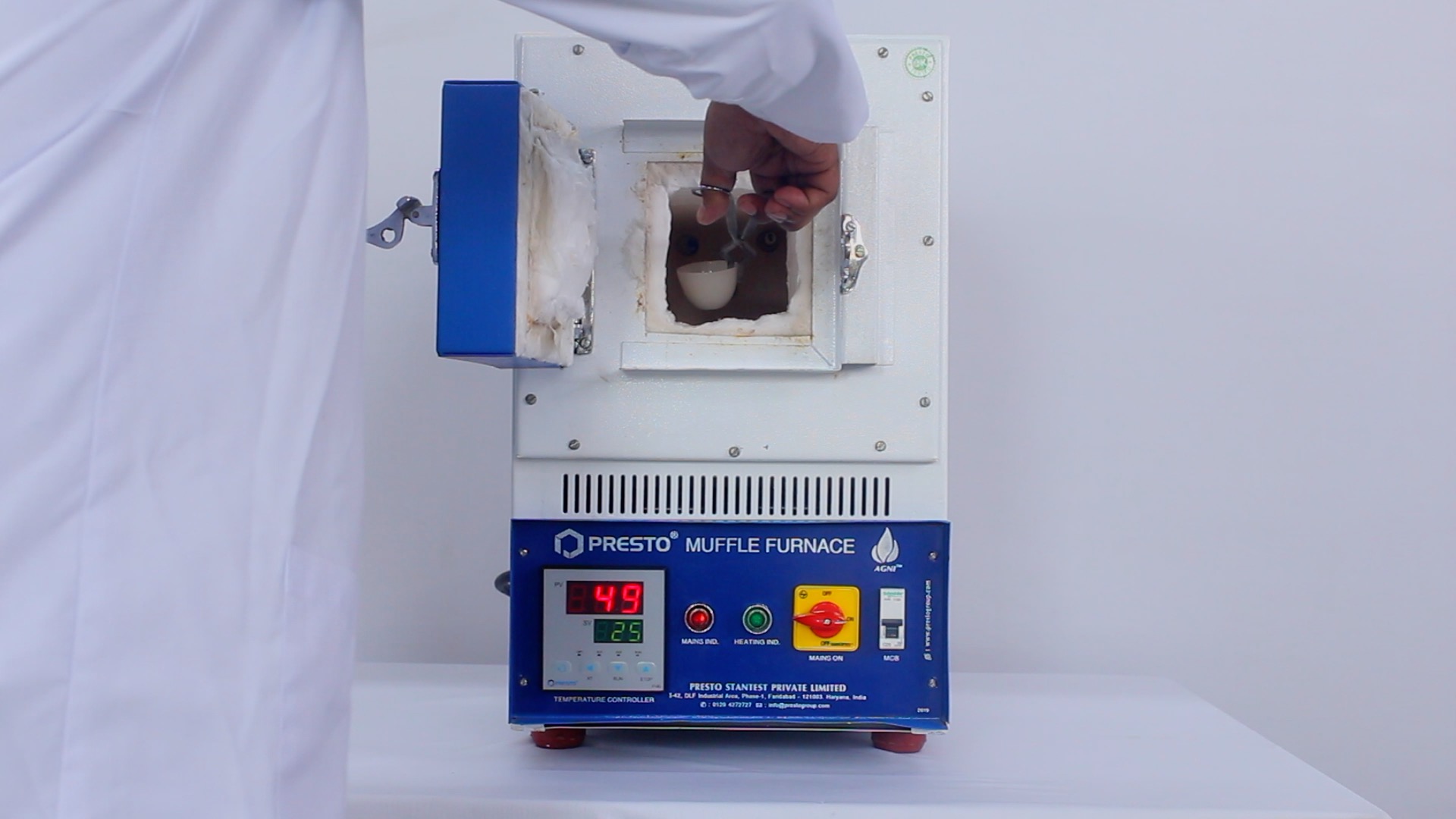

First off, what is the muffle furnace? Imagine a hot oven with a shrine inside where your samples get heated to extreme temperatures. As opposed to your kitchen oven, a muffle furnace segregates the heating element from the chamber where your materials are to be placed. This segregation prevents contamination of your samples by combustion gases. It is like giving your materials a private spa day at high temperatures.

Okay, so here we go with the main part of the conversation: ash content. When we discuss ash content in the context of a muffle furnace, it basically means the residue remaining after burning a sample at a high temperature. No, it's not all the remaining crumbs, it is a piece of important information about your material.

The weight of any incombustible residue that remains after a sample has been incinerated at high temperatures is referred to as ash content. It will tell you how much of the material's original content was incombustible materials that didn't burn up. This could include minerals and metals and also many elements which do not disappear even when the rest of the organic components are incinerated.

Ash content: This measures the percentage content of the ash in the sample. It will tell you about the composition of your material. For instance, when you take a soil sample, too high an ash content may mean there are a lot of minerals in your soil. In the case of plastics, the ash content can tell you that you may have fillers or even contaminants within. It is looking behind the curtain of what's really in your material - such as finding hidden ingredients in your favorite recipe!

Ash content is also vital when regarded through quality control. Every manufacturer, especially in plastics or minerals, has to look after the quality needs, therefore, ash content can be of help in tracking whether the quality needs are being met and so on. For instance, a plastic product may accrue a redundant high ash content; this could mean impurities and excess fillers; the product would not perform to its standards or match par with quality standards. Think of it as getting the right amount of sugar in your cake batter. Too much or too little changes the product. You get the idea, right?

Ash content is controlled in most industries. Whether you are in the environmental business, manufacturing, or even food production, knowing your ash content will fulfill regulatory requirements. It is the same as keeping your automobile's emissions at just below the threshold of the legal limit to pass an inspection and not be guilty of breaking the rules of operation.

Ash content is determined by placing a sample in the muffle furnace and heating it to a high temperature where the combustible material is totally burned. The residue that remains is weighed and then analyzed to find out how much ash content percentage it has. So, here's a short outline of the procedure:

Sample Preparation: Your sample must be completely dry and free of moisture.

Heating the Sample: Place in a muffle furnace and heat it to the recommended temperature. Normally this is about 550°C or more.

Weigh the Residue: Cool the remaining ash, weigh it, and calculate its percentage as compared to its original weight sample.

Mind you, the word "ash" comes from the Old English word "æsce," meaning ash. Not much to say, but something as low-key as ash has historical roots going deep back in history.

A1: High ash is normally an indication of a high amount of incombustible in the sample, possibly minerals or fillers. The implication could be that the material has a good amount of mineral or it could be contaminated.

Ash content measurement is more used for quality control and to comply with the regulations. It ensures a product that is acceptable in quality, free from excessive impurities or fillers that will dampen the performance of the end product.

The ash content in the final product impacts its performance, durability, and appearance. For instance, high ash content in plastics will mean less strength or other different properties. Therefore, it is essential to understand the ash content in determining quality and reliable products.

And that's it: the enigma of muffle furnace ash content is solved! It is not only what is left after heating, but rather speaks of the true quality of your materials, maintaining quality, and especially observing standards. So the next time you turn on that muffle furnace, remember, that it is not just burning out the old but letting the essence of what's left rise.

You have it—a full view of what goes on within a muffle furnace and why keeping up with the filling content is so critically important. Testing for strength, durability, or any property is heavily reliant on handling your test specimens properly. Next time you ignite that muffle furnace, remember: it is not about heating things up; it is about heating them up with precision and care. Happy testing!

Contact us at +919210903903 or send your queries over mail at info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?