The construction of materials that are used as packaging items is extremely precise due to the real-life hassles that they undergo. The most majorly used rigid packaging materials for the transportation of goods from one place to another are corrugated boxes or cartons. These cartons and boxes are made up of a mixture of corrugated sheets assembled together.

Due to the widespread usage and utilization of corrugated sheets & boxes, it becomes vital for manufacturers of the rigid packaging industry to provide high-quality products to the consumers or shippers to enhance the profit margins by recurring consumers due to peak satisfaction.

Evaluating the quality of these products under various tests is necessary and is also widely undertaken by manufacturers. However, an aspect that concerns manufacturers of these cartons is the high-pressure conditions that these cartons have to withstand during the process of transportation. Therefore, evaluation under atmospheric or high-pressure conditions is extremely vital.

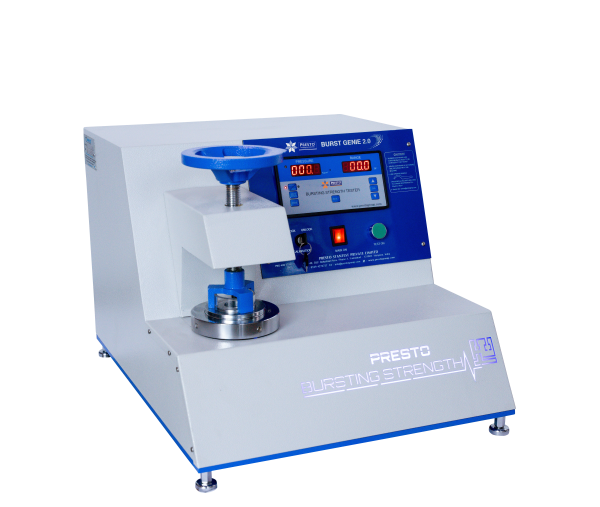

The Presto Group offers top-notch lab testing equipment for simulating real-life atmospheric pressure over corrugated sheets before assembling them into cartons, this avoids the losses that occur due to faulty mass productions and determines the uncertainties (if any) in the initial stages.

The lab testing equipment is called the burst testing machine. The instrument is designed with high-class engineering standards that determine the bursting strength required to rupture a corrugated sheet completely as well as the bursting factor of the specimen being tested. Taking a look at the functioning process of the bursting tester will help you assess the instrument better.

The Bursting tester has gained popularity because of its wide usage in the production process of corrugated boxes in the rigid paper & packaging industries. The instrument offers an extremely simplistic working module that not only ensures an ergonomic testing mechanism but also enhances the speed of achieving accurate test results.

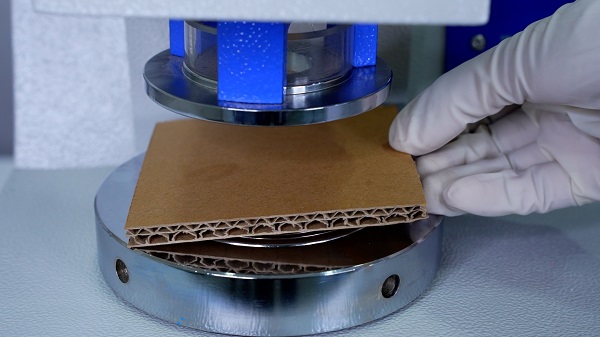

To conduct the bursting strength test, the operator has to make sure that the size of the specimen being tested is bigger than the size clamper of the machine associated above the diaphragm.

The operator can simply adjust the specimen above the diaphragm with the help of the round gripper that has a rotary wheel mechanism for firm clamping of the specimen.

Once the specimen is firmly clamped, the operator can initiate the bursting strength test by turning the instrument on. The instrument has a diaphragm made with neoprene rubber that is adjusted below the specimen. The diaphragm works on a hydrostatic pressure mechanism as the medium used for the exertion of pressure is liquid i.e. lab grade glycerin.

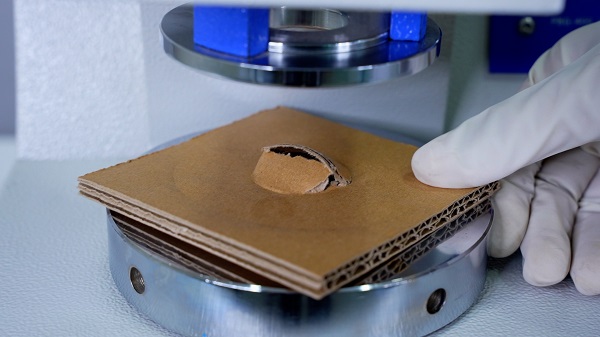

The glycerin is the testing fluid that is displaced at a rate of 95 cc per minute, allowing the neoprene rubber to displace from its original state and exert pressure on the specimen clamped above it due to the displacement caused by hydrostatic pressure.

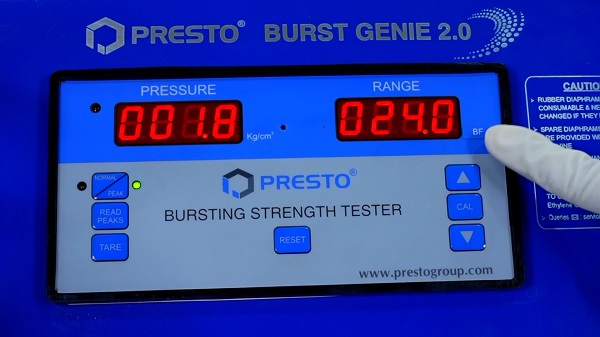

The specimen withstands the pressure from the diaphragm but after the peak value is attained, it bursts or ruptures with a popping sound. The microprocessor-based digital display associated with the instrument determines the peak strength that the specimen can withstand before rupturing.

With the determination of the bursting strength the operator can also get to the bursting factor by using a simple mathematical formula:

Bursting Factor = (Bursting Strength x 1000) / G.S.M of the specimen

This is how the paper burst tester determines the ability of corrugated sheets and related materials to withstand rupturing in a quantifying manner.

The testing becomes facile due to certain attributes that are inculcated within the production of this top-notch instrument by its manufacturer.

The Burst testing machine is a top-notch lab testing instrument that ensures expeditious testing along with accuracy-driven results repeatedly.

The most highly appreciated feature of the instrument is the construction of the diaphragm with neoprene rubber. The diaphragm is the most important part of the test and the Presto Group has made sure to provide maximum durability of the same by using a neoprene rubber that can withstand any atmospheric condition without compromising its mechanical properties.

Another high-end feature of the paper burst tester is the use of lab-grade glycerin to satisfy the hydrostatic working mechanism of the instrument. The lab-grade glycerin is refined at 98% which ensures a displacement speed of 95 cc/ minute, allowing the testing measures to expedite.

The instrument has a very amazing rotary wheel for clamping the specimen firmly on top of the diaphragm ensuring no movement of the specimen during the conduction of the test. This not only simplifies clamping for the operator but also enhances accuracy levels for the manufacturer.

The bursting strength tester also offers a microprocessor-based digital display along with feather touch buttons and a control panel to streamline the testing experience and allow the operator to conduct testing with no or minimal hassle. The memory hold button on the panel also allows the operator to keep track of up to nine recordings and analyze the output of the tests critically.

The Presto Group also provides verification foils along with the instrument for in-built calibration. These verification foils increase the sense of assurance in the minds of manufacturers and allow the operator to conduct the test without the worries of uncertainties and inaccurate test results.

The final feature is the construction of the instrument. The burst testing machine is offered with a robust build because of its mild steel surface. The mild steel material is also coated with 7 7-layer powder coating to avoid rusting & corrosion for a long period of time.

To achieve high levels of accuracy in determining the bursting strength and the bursting factor of a corrugated sheet or any other related material, you can get your hands on the burst testing machine without any further delay. For more information visit our website and to place an order, call us at +91 9210903903 or e-mail us at info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?