The usage of bottles is widespread all around the globe as they are opted as the primary products for packaging, deliverance, and consumption. These bottles not only carry beverages & liquors but also carry extremely important medicines which are crucial to be kept away from any sort of contamination.

This is the reason that operators have to make sure that there is no leakage and that the bottle is perfectly integrated. The assessment of seal integration of the walls of the bottle becomes vital at this stage of production. However, the evaluation of the bottle’s seal integrity is extremely difficult and therefore the manufacturers struggle to deliver the required product.

To curb this hassle of evaluating the bottle’s seal integrity, the Presto Group has offered a highly advanced and simplistically designed lab testing instrument called the vacuum leak tester for PET Bottles.

The vacuum leak tester for PET bottles has revolutionized the testing norms with such an easy way of testing. Taking a look at the functioning mechanism of the instrument will explain the conduction of the vacuum leak test.

The PET bottles are evaluated against their integrity to make sure that the fluid packed inside does not get contaminated due to exposure to the environment.

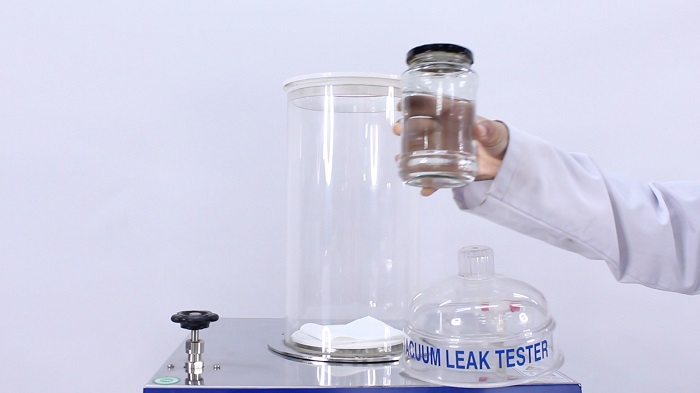

To commence the test, the operator must make sure that the size of the PET bottle being tested inside the vacuum leak testing machine does not exceed the size of the desiccator.

The operator can place the PET bottle inside the desiccator. The operator must make sure to close the desiccator lid to eradicate the scope of the external atmosphere hampering the inside atmosphere.

The vacuum leak testing machine ensures that the operator can keep a check on the specimen at all times during the conduction of the test for a better and more precise assessment.

The operator can now turn the air pressure from the air pressure knob on which ensure the air pressure elevation inside the desiccator through the inlet port.

The bottle that is kept inside the desiccator in an upside-down position will face a formation of vacuum forcing the fluid inside the bottle to exit out of the bottle closure. In the case of any uncertainty or leakage, the fluid inside the bottle will flow out.

The testing processes can be adjusted with the help of the control panel that is equipped with certain features to ensure precise & accurate testing measures of the vacuum leak tester.

Once the time & air pressure adjusted by the operator is achieved as seen on the microprocessor-based digital display and the pressure gauge respectively, the operator can simply remove the desiccator lid and take the specimen out.

In case of any leakage, the tissue kept in the desiccator bowl will be wet and show traces of the fluid inside the bottle.

The vacuum leak tester for PET bottles attains high levels of accuracy and simplifies the testing measures with absolute ease & facile due to the inclusion of top-notch features.

The vacuum leak tester for PET bottles is equipped with highly advanced attributes that aid manufacturers from all across the industries related to fluids & packaging.

The most prominent feature of the instrument is designing of the desiccator as an acrylic chamber, which ensures transparency and allows the operator to keep a check on the specimen during the conduction of the test.

The lab testing instrument is equipped with an inlet port for the precise distribution of the vacuum-producing air pressure inside the acrylic chamber, ensuring the testing is even and accurate.

The vacuum leak test is performed with maximum accuracy due to the futuristic microprocessor-based digital display associated with the control panel that allows the pre-setting of the timer, enabling the operator to adjust the timing of the test beforehand.

The control panel is also an amalgamation of both feather touch controls and on/off switches that elevates the testing experience by promoting single-handed operations and achieving pinpoint accuracy by indicating the air pressure on the dedicated air pressure gauge.

The instrument carries a lot of other features like seal integrity due to desiccator lid insulation, robust construction of the instrument, etc. All these combine and enhance the testing measures by making it more accuracy-driven & operator-friendly.

To get yourself a top-quality vacuum leak tester for PET bottles, you can reach out to us through our website. The website offers all the necessary information and answers to all your questions.

If you want to place an order for the vacuum leak tester for PET bottles, place a phone call at +91 9210903903 or e-mail us at info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?