Ensuring the durability of packaging materials against shock and impact is paramount for improving packaging design and quality. Drop testing is widely utilized, employing tools like Single Wing and Dual Wing Drop Testers to assess shock resistance. These testers feature double column guidance, adjustable height for dropping samples, and ensure stable and reliable operations, facilitating tests on various surfaces and angles.

Drop testing plays a crucial role in quality assurance, ensuring products can withstand the challenges of transportation and handling. Post-drop functionality is vital across industries, ranging from consumer goods to military equipment.

Drop Testing provides essential data for diverse products and industries, aiding in prototype development and regulatory compliance.

Presto offers state-of-the-art drop testing capabilities, accommodating various heights and impact surfaces, and adhering to ISTA, ASTM, and ISO standards. With a proven track record across aerospace, automotive, FMCG, medical devices, and other sectors, Presto ensures confident product durability assessments.

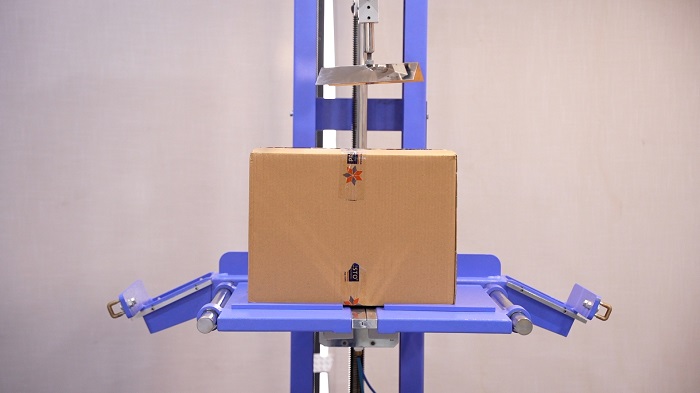

The Zero Altitude Drop Tester features an advanced structure enabling rapid separation between cargo bracket and packaging specimen during the drop process, ensuring low impact vibration and reliable stability. The cargo bracket accelerates at over 4G, ensuring precise drop intensity.

Understanding applicable standards and factors influencing product ruggedness is essential, as drop intensity can range from extreme to lower-intensity "tumbles."

Drop testing evaluates a product's resilience against accidental drops during its lifespan. It involves dropping products from fixed heights onto flat surfaces in specified orientations, examining for damages post-drop.

Factors influencing test severity include drop frequency, height, surface hardness, and temperature. ASTM D5276 serves as a standard for evaluating package resilience against free falls, crucial for product comparison and performance evaluation.

The test involves conditioning specimens, packing them as per shipping norms, and marking them appropriately. Measurements are taken from various surfaces or edges to the impact surface, and results are documented following ASTM guidelines.

Presto offers comprehensive testing equipment for packages of all sizes, ensuring compliance and facilitating product development.

Understanding drop testing standards and their limitations, along with the impact of drop surfaces on product damage, is crucial for manufacturing companies. Equating test methods with product resistance is essential for accurate evaluation.

Drop testing assesses a product's or package's ability to withstand being dropped. Since accidental drops are common, it's crucial that a product or package is designed to endure a minimum defined number of these impacts. (It's important to note that products are not intentionally designed to be dropped.) Before testing, the number of drops, drop height, and surface onto which the product will be dropped must be specified.

During the test, a product is dropped in a "free fall" manner a predetermined number of times, from a fixed height, onto a flat surface. (Objects are released from a stationary position and are not thrown or directed.) The test unit is positioned in a specified orientation (for example, display down, display up, on its side, etc.) for each drop.

Following each drop, the unit is inspected for damage. Units that exhibit significant loss of functionality, such as issues with powering on, capturing data, or allowing data entry, after drop testing, do not pass the test.

Several factors can increase the severity level of testing, including increasing the required number of drops, increasing the height above the surface, using a harder drop surface, and decreasing the temperature of the unit during a drop (as products become more rigid with respect to impact).

The ASTM D5276 standard is employed to evaluate a package's ability to withstand sudden shock from free fall. As a lab certified by ISTA and ISO 17028, we understand the importance of free fall testing for loaded packages.

ASTM D5276 outlines the procedure for assessing loaded boxes, cylindrical packages, bags/sacks, and pouches through the free-fall drop method.

The scope of ASTM D5276 is most appropriate for packages that undergo manual handling throughout the distribution cycle.

Drop apparatus must enable accurate control of drop from a specified height, ensuring correct orientation upon impact.

Impact surfaces must be horizontal, flat, and rigid, meeting specific size and weight criteria.

Prior to testing, specimens must be conditioned, and packaging must replicate real shipping conditions. You can easily evaluate the drop tolerance of carton packages with this high quality testing instrument.

ASTM D5276 outlines the procedure for testing loaded boxes, cylindrical packages, bags/sacks, and pouches by the free-fall drop method. For packages that are less than 110lbs. This test will satisfy some ISO standards.

Additionally, ASTM D5276 also serves as a means to evaluate the package’s ability to protect its contents during free fall. This test can be used to compare package packages.

Different designs can be tested and compared for protective capability. It is also beneficial to perform this test to observe the failure of a package and the resulting damage to its contents.

The ASTM D5276 standard is best suited for packages that are typically manually handled at some point throughout the distribution cycle. If a package is so large or heavy that it cannot be handled manually, then there may be a different test that is better suited for optimal test results.

There are specific requirements for the free-fall drop test equipment.

Basic Requirements state that the drop apparatus must:

There are different requirements when utilizing a rupture hazard or testing certain fiber drums and very large packages.

The test specimen should be conditioned prior to beginning the ASTM D5276 test. The test specimen and number of samples should allow for an adequate representation of a performance in the field. ASTM recommends that in the absence of a sampling plan, at least three samples should be tested. You can easily test various types of packaging materials with Presto drop tester.

Whether testing for the ability of the product/container/package to withstand rough handling or its protective capability to safely transport its contents, it is recommended that the container/package is packed with the actual contents that it will be transporting. It is also acceptable to pack the container/package with simulated contents when testing for handling.

Regardless of the contents, the sample must be closed or sealed in the same manner that it would be for shipping. This is done well in advance of the test so that the package will reach its normal shipping conditions before testing.

To conduct the ASTM D5276 free-fall drop test, the product/package must be marked according to their faces or positions. The test specimen will then be positioned on the drop apparatus according to the type of drop (flat edge, edge drop, etc.) that will be tested.

To accurately measure the height of the drop for purposes of ASTM D5276, measure from the bottom surface, edge, or corner, to the impact surface. The testing laboratory will record measurements and drop data and complete a report following the guidelines outlined in the ASTM D5276 standard.

Presto Drop Testing Equipment can accommodate flexible and rigid packages of all sizes, including large pallets. Our team strives to give our customers more time and energy on training them to use the equipment and get reliable test results.

Request a quote to receive testing services customized to your specific needs. Have a question about drop testing of products/loaded packages? Contact us and we will determine the best course of action.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?