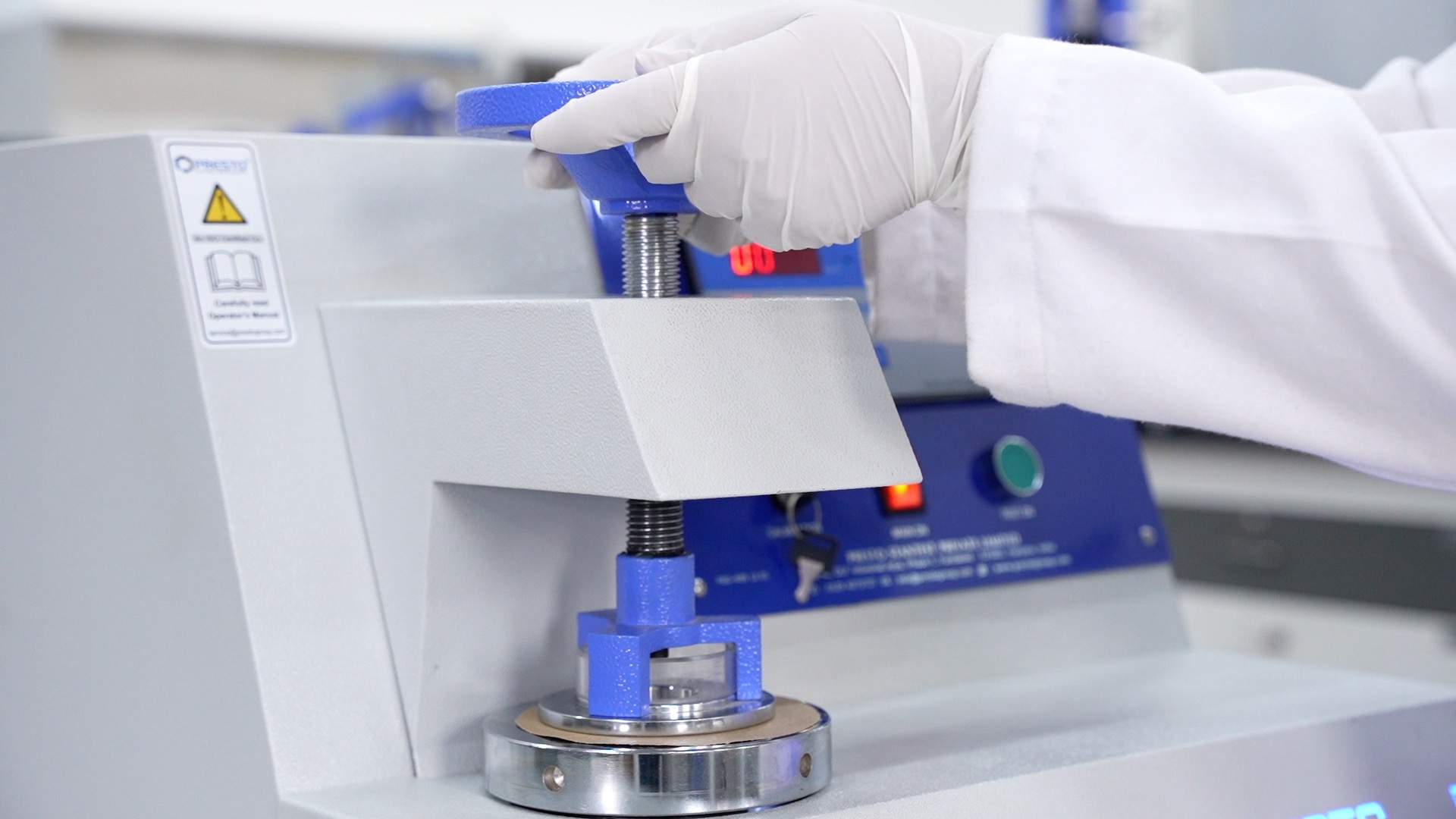

The overall product experience may be affected by poor quality and durability of packaging for your customers. The Packaging Testing’s Bursting Strength Tester ensures structural integrity of your products. This testing instrument can efficiently measure the bursting strength of your packaging and yield accurate results. Thus, reducing risks of damaged packaging and enhancing overall customer satisfaction.

The tester helps manufacturers in identifying the weaknesses in their packaging and ensuring longevity in the long run. Making it an indispensable tool in the production process.

This advanced testing equipment has several key features:

This feature is critical for manufacturers and quality control teams because it removes the need for manual computations, which reduces human error while providing consistent and precise results. The Bursting Strength Tester gives vital insights into the structural integrity and performance characteristics of packaging materials by automatically calculating burst factors that represent the material's strength-to-weight ratio. This functionality not only simplifies the testing process but also improves efficiency in production scenarios where quick and dependable data analysis is critical.

The Bursting Strength Tester has a simple single-button operation interface that is intended to be user-friendly. This user-friendly design enables operators to easily begin tests, reducing training requirements and permitting seamless integration into current quality control methods. The simple operation allows users to focus on analyzing test findings rather than navigating complicated settings, increasing workflow efficiency and productivity.

Real-time monitoring and visualization of test results is made possible. The sophisticated LED panel displays crucial parameters such as pressure levels, deformation properties, and burst occurrences. This capacity allows operators to make educated decisions based on precise and reliable test findings, guaranteeing compliance with strict quality standards and regulatory requirements. Furthermore, the microprocessor-based technology improves the tester's reactivity and stability, resulting in consistent performance across different testing circumstances and material kinds.

The peak hold capability improves the Bursting Strength Test usefulness. This feature enables the tester to record and save the maximum test result value obtained throughout each testing cycle. By storing this peak value in memory, operators may do thorough analyses and comparisons across several samples, making trend analysis and performance benchmarking easier. The peak hold function is very useful in quality assurance operations, where determining the maximum burst strength of materials is crucial for optimizing product design, packaging configurations, and supply chain logistics.

It has adequate storage space for up to 9 test readings, which aids in data management and tracking. This functionality allows operators to save and refer to prior test data, ensuring quality control processes are consistent and audit compliance is met. Manufacturers may analyze material performance over time, detect trends, and apply proactive actions to eliminate possible risks related to packing integrity and product dependability by keeping a complete record of test findings.

Accurately analyzing bursting strength manufacturers ensures that producers can consistently produce high-quality items. Companies can design packaging that appropriately protects their contents during shipping and storage if they understand the maximum pressure that materials can endure before exploding. This dependability not only increases consumer happiness by lowering the possibility of damaged items but also promotes the brand's image of dependability and durability in the market.

By preventing product failures caused by poor packing, the tester can prevent manufacturers from incurring huge losses. Manufacturers may considerably decrease the costs of product recalls, replacements, and customer complaints by discovering and correcting flaws in packing materials early in the production process. Furthermore, optimizing package design using correct bursting strength data reduces material waste and total packing costs, resulting in increased operational efficiency and profitability.

Adhering to industry standards such as IS 2508:1984(R2003) and ASTM D1709-16A is crucial for firms seeking regulatory compliance and quality control processes. The tester confirms that packaging materials fulfill these stringent criteria, assuring producers that their goods meet regulatory requirements and industry norms. This compliance not only reduces the risks associated with noncompliance, but it also allows for easy market entrance and acceptance of products in numerous countries, as well as increased market profitability.

The bursting strength tester may be utilized with a variety of packing materials and combinations. The tester can suit a wide range of testing demands, including single-layer papers, corrugated boards, and composite materials. This adaptability enables producers to assess the bursting power of various packaging materials under varied situations, allowing them to design packaging solutions to specific product requirements and environmental considerations. As a consequence, the tester is a versatile and necessary instrument for improving packing performance and maintaining product integrity across the supply chain.

In industries like manufacturing, where product integrity is critical, the tester helps evaluate the appropriateness of packing materials for specific applications, assuring consistent quality and dependability. Similarly, sectors such as textiles employ bursting strength tests to determine fabric durability for a variety of applications, ranging from garments to industrial textiles. The digital bursting strength tester offers significant advantages in a variety of sectors. In packing and logistics, it guarantees that materials can endure the stresses of shipment and handling, lowering the risk of product damage and loss. Manufacturers rely on precise bursting strength tests to optimize package designs, improving product protection while reducing material waste.

Optional features meet a variety of testing purposes and user preferences. Pneumatic and computerized versions provide greater automation and control capabilities, allowing for a variety of operating needs. Models with built-in printers provide for instant documenting of test findings, easing data management and compliance reporting processes.

HURRY AND BUY THE BURSTING STRENGTH TESTER!

To know the Bursting Strength Tester Price get a quotation now. You may reach out to us at +919210903903 or email us at info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?