The usage of corrugated boxes is extremely prevalent in various industries. The more the usage, the better the quality you get. Therefore, it becomes crucial to deliver a top-notch quality of corrugated boxes all across the industries. The quality needs to be up to the mark in order to safeguard the items kept within these boxes during storage and transportation.

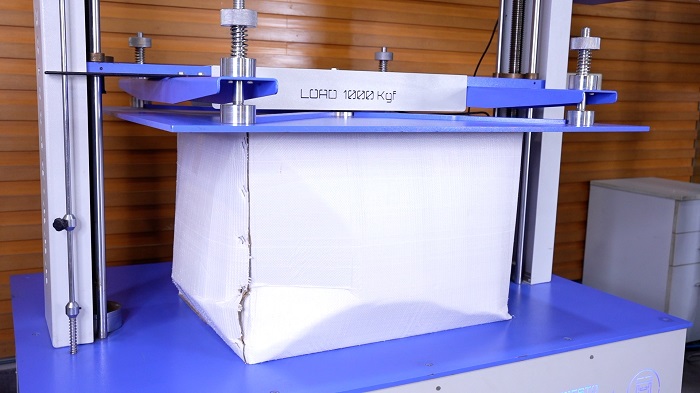

The quality of these corrugated boxes is ensured by a lab testing instrument called the box compression tester. The instrument is responsible for determining the ability of these corrugated boxes to withstand compressive force applied to them during stacking by creating real-life stacking storage simulations.

Manufacturers of the paper & packaging industry widely use this instrument to conduct box compression tests and identify the deformity that takes place after withstanding compression to a certain level. This helps them to take corrective measures as per the uncertainty, enhancing the quality of these boxes.

The instrument is equipped with a motorized compressive platform that forces downward pressure on the corrugated box with the help of circular lead screws. The corrugated box withstands the compressive force to a certain extent as per its quality and then deforms. The computerized mechanism of the box compression tester simplifies the conduction of this test by recording and indicating the peak compression value as well as the deflection or deformation of the box.

Once the box compression tester computerized records all the values, the operator has a provision to extract the data into tabular formats for a critical analysis. The data can be extracted into Excel & PDF formats.

However, there are some key preparations that a corrugated box should undergo before the box compression test is conducted for error-less results consistently.

To achieve higher levels of accuracy it is vital to prepare the specimen i.e. the corrugated boxes that are going to be tested as per certain guidelines.

To make the functioning of the box compression testing machine, the Presto Group has made sure to add a whopping amount of features, making the usage & working facile for the operator and accuracy-driven for the manufacturer of corrugated boxes.

The box compression testing machine is equipped with top-quality features, ensuring highly accurate results consistently as well as promoting single-handed operations to aid the manufacturer.

To ensure an even higher level of accuracy, the operator must take care of certain installation parameters of the box compression tester computerized.

To conduct a flawless box compression test, it becomes extremely crucial to install the lab testing instrument in the correct manner.

The box compression tester manufacture in Delhi NCR i.e. the Presto Group is proud of this ergonomically designed lab testing instrument as it has aided a lot of manufacturers from the paper & packaging industry.

If you also want to achieve greater quality levels of your manufactured corrugated boxes, you can buy the amazing box compression tester computerized directly from the manufacturers in Delhi NCR. To know more about the instrument visit our website or to get your questions answered, you can call us right away at +91 9210903903 and also e-mail us stating your problem or give feedback at info@prestogroup.com. Get your hands on a box compression tester today.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?