A scuff resistance tester is a tool used to assess the potential of substances, coatings, and finishes to face up abrasive pressure and scuffing. Scuffing is not a rare difficulty, wherein surfaces are broken because of friction, causing unpleasant marks or degradation of the cloth`s look and overall performance.

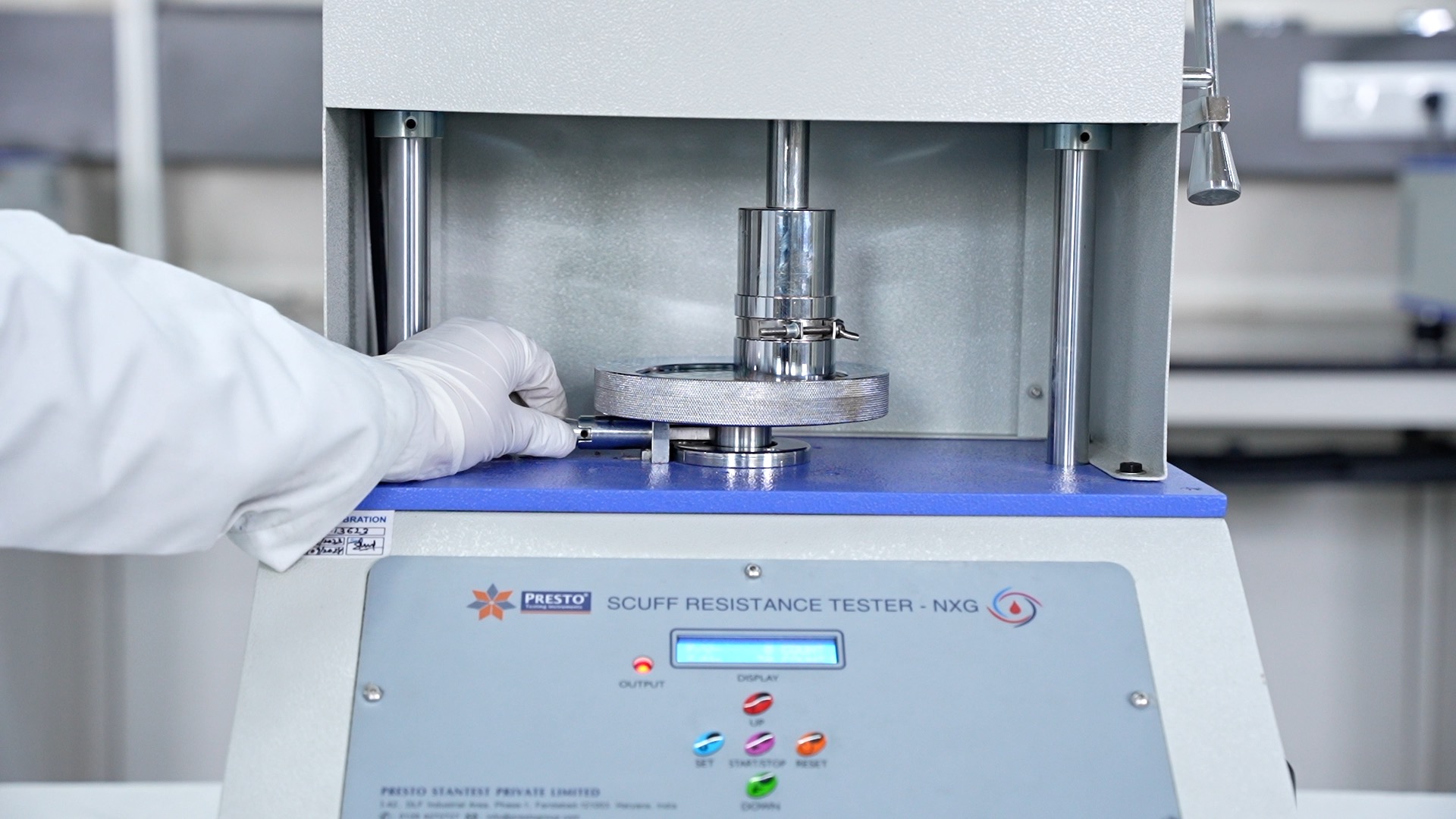

The tester generally includes a base platform, a test specimen holder, and an abrasive or rubbing issue. During testing, the cloth or coating under examination is positioned at the platform. An abrasive or rubbing detail is then implemented with managed stress and movement to simulate normal pressure conditions. The tester video displays the units of the quantity of harm or pressure as a result of the abrasive action, imparting treasured information about the cloth`s scuff resistance.

Various fashions of scuff resistance testers are available, starting from easy guide instruments to state-of-the-art computerized systems. Automated testers regularly characterize programmable settings for stress, speed, and duration, and logging abilities for certain analyses.

One of the number one troubles that scuff resistance testers cope with is comparing how properly substances and coatings can bear normal pressure and wear and tear. Many merchandise, from floors to automobile finishes, are challenged by friction and abrasion throughout use. Scuff resistance testers assist producers in deciding if their merchandise can preserve their look and capability over time.

In industries wherein sturdiness is critical, including automobile, aerospace, and client goods, making sure of product quality is vital. Scuff resistance testers offer a standardized technique to evaluate the overall performance of substances and coatings, assisting producers to preserve tremendous requirements and keep away from troubles associated with untimely pressure or harm.

Many industries have precise requirements for scuff resistance that merchandise has to meet. Scuff resistance testers assist corporations make certain their merchandise follows those requirements. For example, requirements like ASTM D4060 for abrasion resistance or ISO 7784-2 for scuffing resistance offer pointers for test strategies and proper overall performance levels.

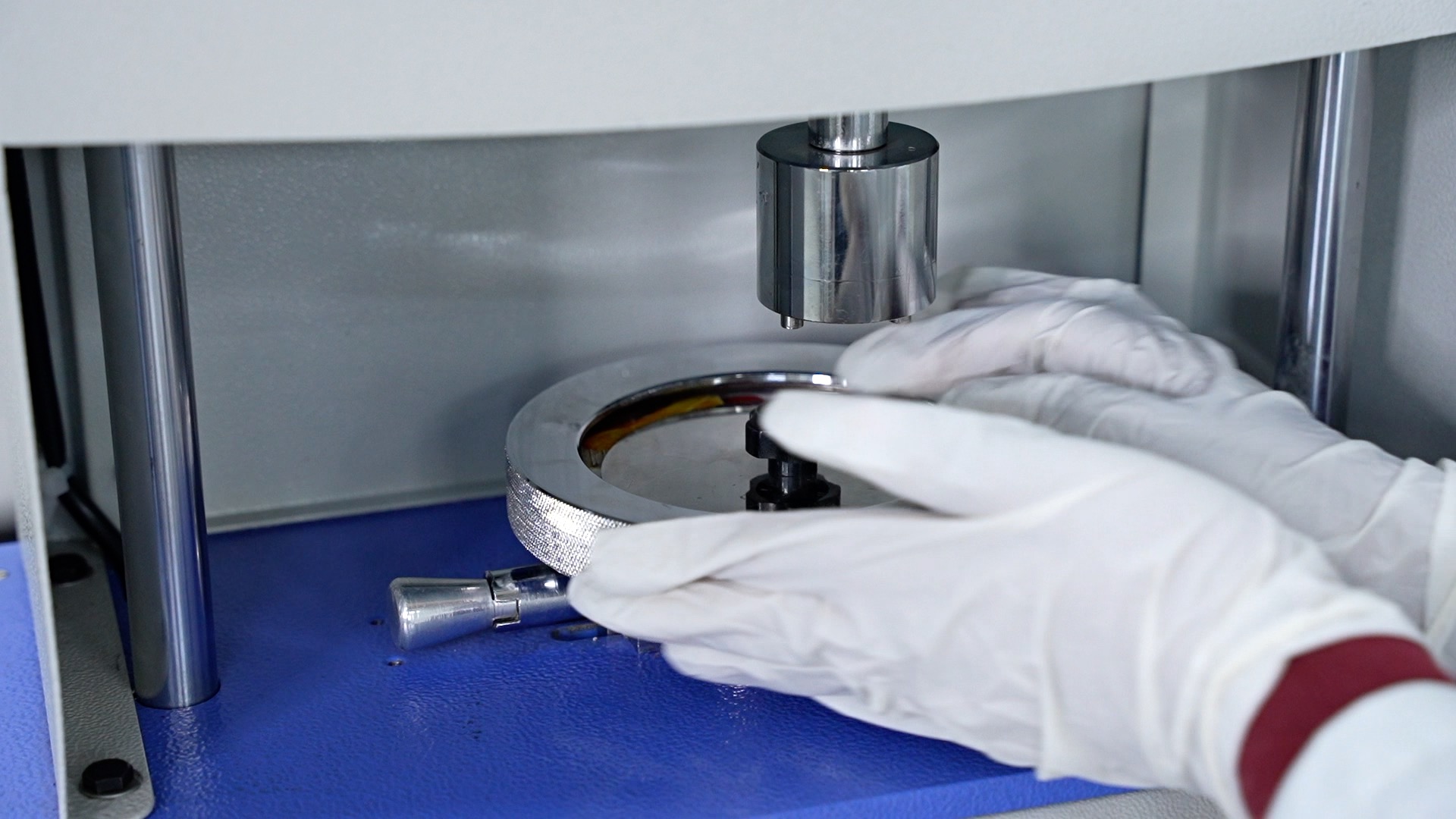

To carry out a scuff resistance test, a pattern of the cloth or coating is ready and secured at the tester`s platform. The test specimen is generally wiped clean and conditioned to make certain that the consequences mirror the cloth`s overall performance under ordinary conditions.

An abrasive or rubbing issue is implemented to the test specimen with managed stress and motion. This issue will be a rotating disk, a brush, or any other abrasive cloth, depending on the tester's design. The motion simulates real friction that the cloth would possibly come upon throughout use.

After the test, the extent of damage or wear on the test specimen is evaluated. This could involve visual inspection, measuring the depth of abrasion, or assessing changes in surface properties. The results are compared to predefined standards or benchmarks to determine the material’s scuff resistance.

Automated scuff resistance testers often include data logging features that record various parameters of the test, such as pressure, speed, and duration. This data is essential for detailed analysis and quality control, providing insights into the material’s performance and durability.

The period of a scuff resistance test depends on the specific test method and the material being evaluated. A standard test can range from a few minutes to several hours. For example, a test following ASTM D4060 might involve several thousand cycles of abrasion, which can take several hours to complete.

Scuff resistance and abrasion resistance are associated, however, they have diverse properties. Scuff resistance measures a cloth`s capacity to face floor marks and harm as a result of friction or rubbing, usually under lighter pressure. Abrasion resistance, on the other hand, assesses how properly a cloth can undergo greater wear and tear, inclusive of repeated rubbing or scraping which could motivate greater widespread floor loss or harm. While scuff resistance is involved with superficial harm, abrasion resistance looks at usual sturdiness and fabric loss.

Want to know the scuff resistance tester price? Reach out to us through a phone call at +919210903903 or directly dropping us an e-mail at info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?