At Presto, we understand how greatly friction serves the packaging industry. Packaging materials need to offer special characteristics to not slip and be properly handled while being transported and stored. Here emerges the Coefficient of Friction Tester, and our COF Tester further assists manufacturers and quality control teams in assessing the frictional properties of various materials, thus, helping in controlling the quality and safety of products in a better way.

A coefficient of friction tester is an instrument meant for specialized measuring to determine friction between surfaces while sliding against each other. The friction coefficient describes, as a numerical number, the tendency of one material over another. In the case of packaging materials, it is essential since it determines their resistance to sliding under given load conditions.

This equipment ensures that your packaging materials are neither too slippery nor too resistant to movement, thus achieving the right balance for transportation and handling processes. It prevents product damage during transit by confirming whether the materials achieve the standards on friction, thus ensuring reduced occurrences of slips, falls, or even damage caused to items.

Controlling the friction coefficient is highly important in ensuring that the products are safe and the integrity of the packaging is maintained in the packaging industry. For instance, if it is highly frictional, then the packages stick to each other, making them very inconvenient to handle. Low friction leads to slippage causing loss through falling products during transportation or storage-very huge losses.

The friction properties are measured in the paper, plastics, and films by a COF Tester. This information is important for the quality control team to ensure that the materials chosen for the packaging of products have the desired performance.

Accurate Results: The results from the COF Tester of Presto are accurate so that there is an assurance that the frictional properties of the material are reliable.

Ease of Operation: The tester has a friendly interface, which helps even a person not related to test equipment to operate it.

Versatility: The COF Tester can test materials ranging from paper to plastic and laminates, thus suitable for large-scale applications.

Compliance: The COF Tester will ensure that the packing of the products is in compliance with international standards. In other words, it ensures that the manufactured quality product meets global expectations of quality.

Durability: With high-quality materials, Presto's COF Tester will be in use for a long time and requires minimal maintenance.

Packaging Materials: The COF tester provides frictional requirements to packaging materials which are plastic films, cardboard, and paper, to ensure more handling or transportation efficiencies.

Better Quality Control: This coefficient of friction can thus be reasonably measured, then checking on the continued quality of the manufactured goods to prevent defects from them.

Economical Savings: Since the companies get surety of proper frictional characteristics for the packaging materials, there is a lesser possibility of material waste and damage while in transit coupled with cost savings.

Safety: Materials well tested ensure safer handling and transportation, thus reducing the risks of accidents due to slippage or other failures associated with friction.

Compliance with Industry Standards: Presto's COF Tester can enable companies to adhere to not only the quality standard pertinent to the industry but also the international standard, so it has become easy to expand the business base beyond national borders.

Improved Productivity: The production processes become streamlined by providing reliable data from the COF Tester so that material does not fail to comply with frictional requirements and delay is not created unnecessarily.

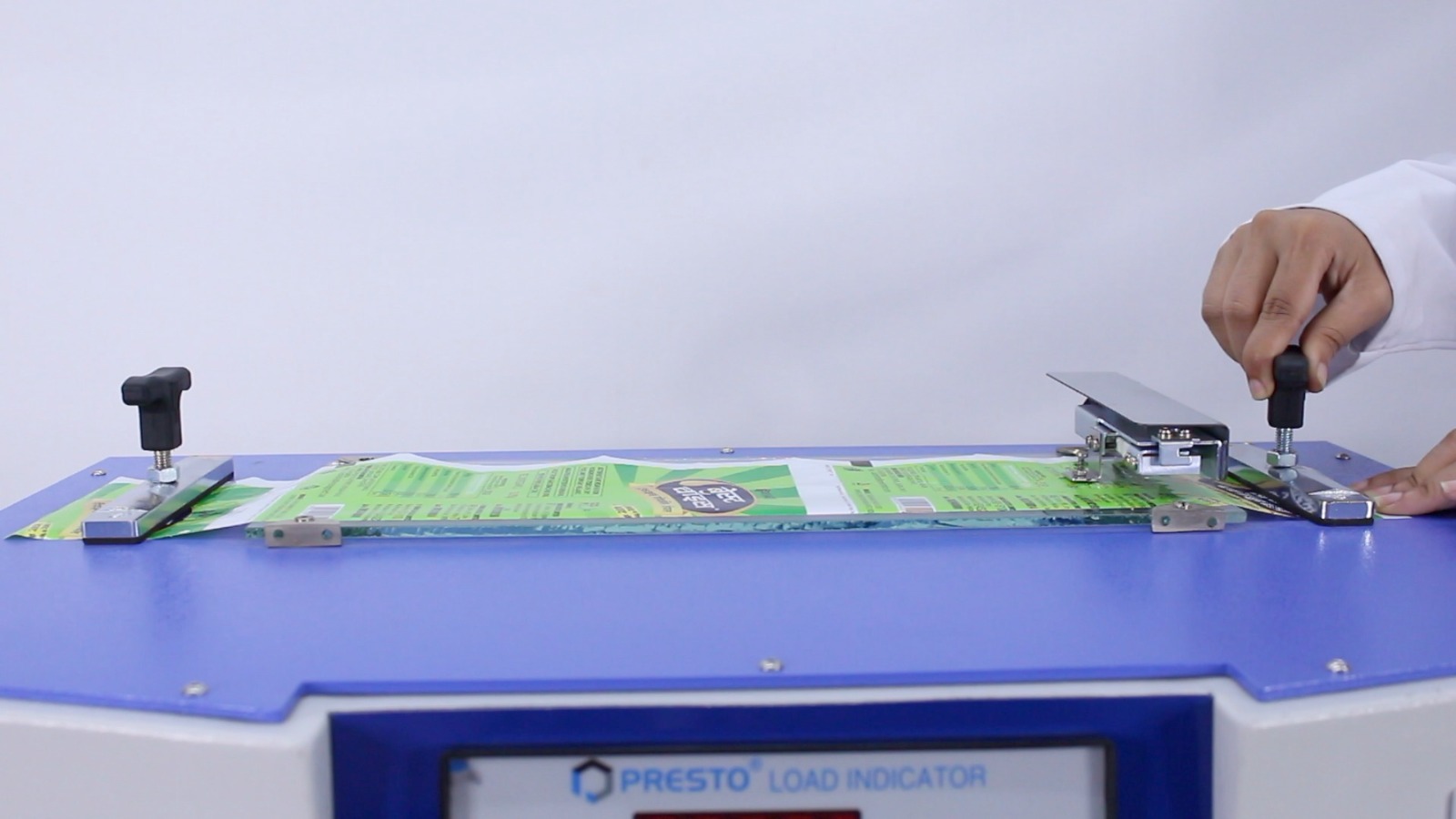

It operates under the principle of placing a sample of the material on a flat surface and then moving another material over it under control. Force or magnitude is measured which then calculates the coefficient of friction. This, therefore helps the manufacturers to determine if the material's surface properties meet the set standards for their specific application.

The test conditions can be varied with temperatures and pressures to simulate actual conditions. Manufacturers can ensure the durability and reliability of their products by simulating transportation or storage conditions that the packaging materials will experience during transport and/or storage.

In this competitive marketplace today, the reliability of packaging material and safety are crucial in not compromising the integrity of the packaged products. This is precisely what a Presto's Coefficient of friction tester offers, and what customers need, exactness, accuracy, and dependability in guaranteeing that their materials fulfill any guideline expected in the business. It has broadly been applied in different areas like automobiles, materials, and drugs. Along with its capabilities for optimizing its materials towards safe and efficient handling, it provides greater value to companies.

A good investment in COF Testers reduces the percentage of damage caused to the products, high levels of customer satisfaction, and increases operational efficiency.

1. What is the coefficient of friction, and what difference does it make?

The coefficient of friction is, as a rule, the obstruction between two surfaces while sliding against each other. Such is the determination of handling properties of packaging materials and safety during transport.

2. How Does the COF Tester work?

A COF tester determines the amount of force required to slide one material over another while under controlled conditions and from this, it determines the friction coefficient to assess the sliding property of the material.

3. What Industries Could Utilize a COF Tester?

Packaging, automotive, textiles, and pharmaceuticals are some industries that could utilize a COF tester to ensure their materials pass friction standards before allowing them to be moved and processed in a safe and efficient way.

Contact us at +919210903903 or send your queries by mail at info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?