Let me put it into perspective: you are outside in the rain, and all you have is a sponge. Yes, that is right! A sponge! After a little while, when those drops of rain start to hit, naturally your sponge starts to become saturated-get heavy and soaked-and thereby becomes an utterly useless form of protection. Now imagine that sponge replaced by an umbrella: sturdy, dependable, and protective. No matter how hard it rains, your umbrella intercepts the rain so you stay dry underneath.

In the paper and packaging industry, the reality was that one would either be drenched like a sponge or remain dry under an umbrella. The Cobb Sizing Tester quantifies how much water or liquid a material can hold-literally like identifying whether your paper is a sponge or an umbrella. That sounds pretty important, doesn't it?

Water: the elixir of many processes, but when it involves paper, packaging, and even specific textiles, it can be a silent destroyer. Picture this: a beautifully packaged product ready for shipping. The packaging is spotless, the design faultless. But what happens when it encounters moisture during transport? If the substrate was too absorptive, you could have created a wet mess in a well-crafted package that not only doesn't look good but destroys the integrity of your product from the inside.

That's where a hero comes in. The Cobb Sizing Tester allows you to run such tests, and rest assured that packaging with such materials would stand up to the best effects of moisture on form, function, and appeal.

So what exactly is this Cobb Sizing Tester? Well, essentially, it's like litmus to check just how waterproof/water-resistant your paper and packaging materials are. Put simply, the Cobb Sizing Tester provides a measure of how much water a paper or board can absorb in a given amount of time. In other words, it tells you whether your material acts like a sponge or an umbrella.

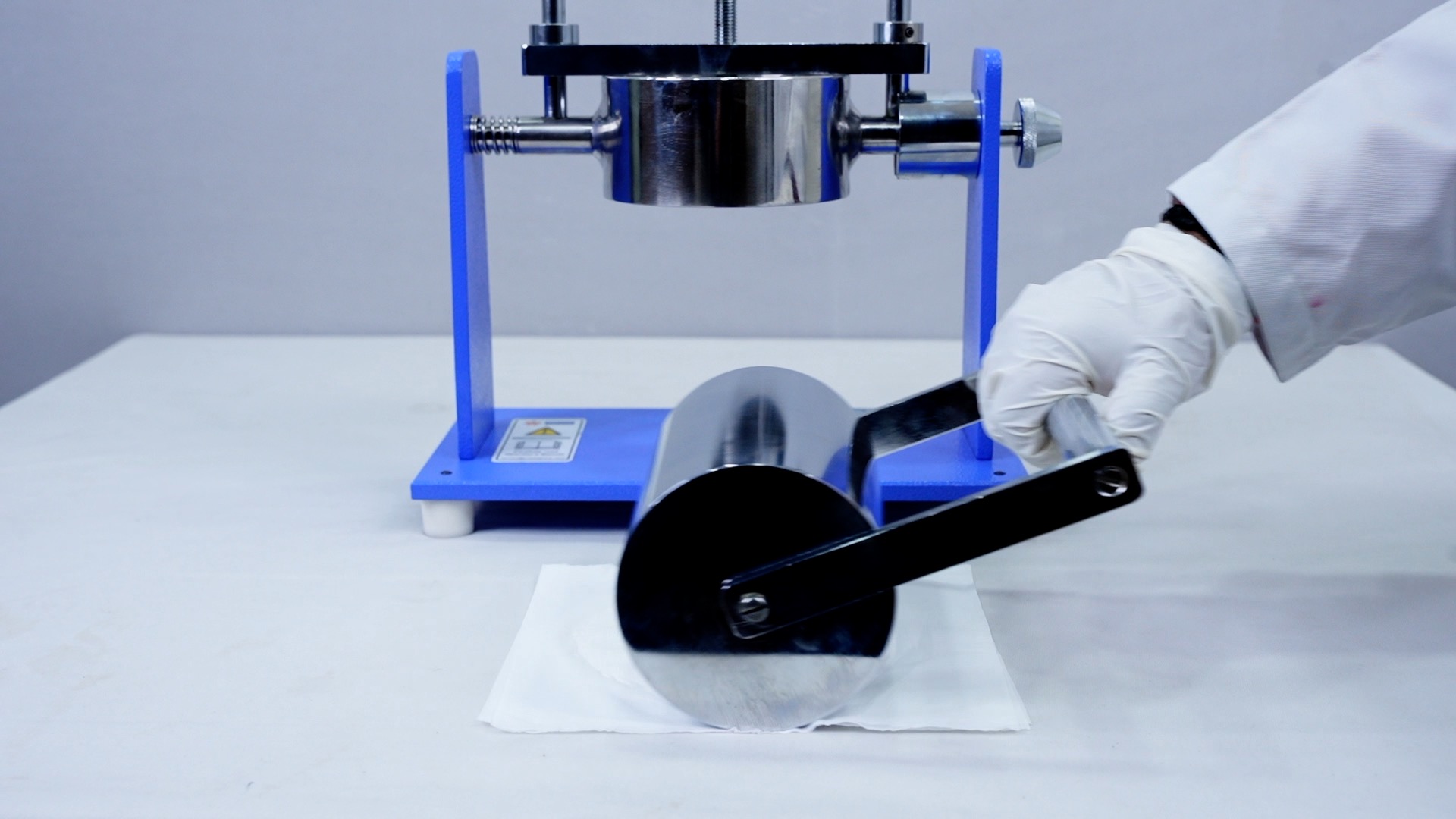

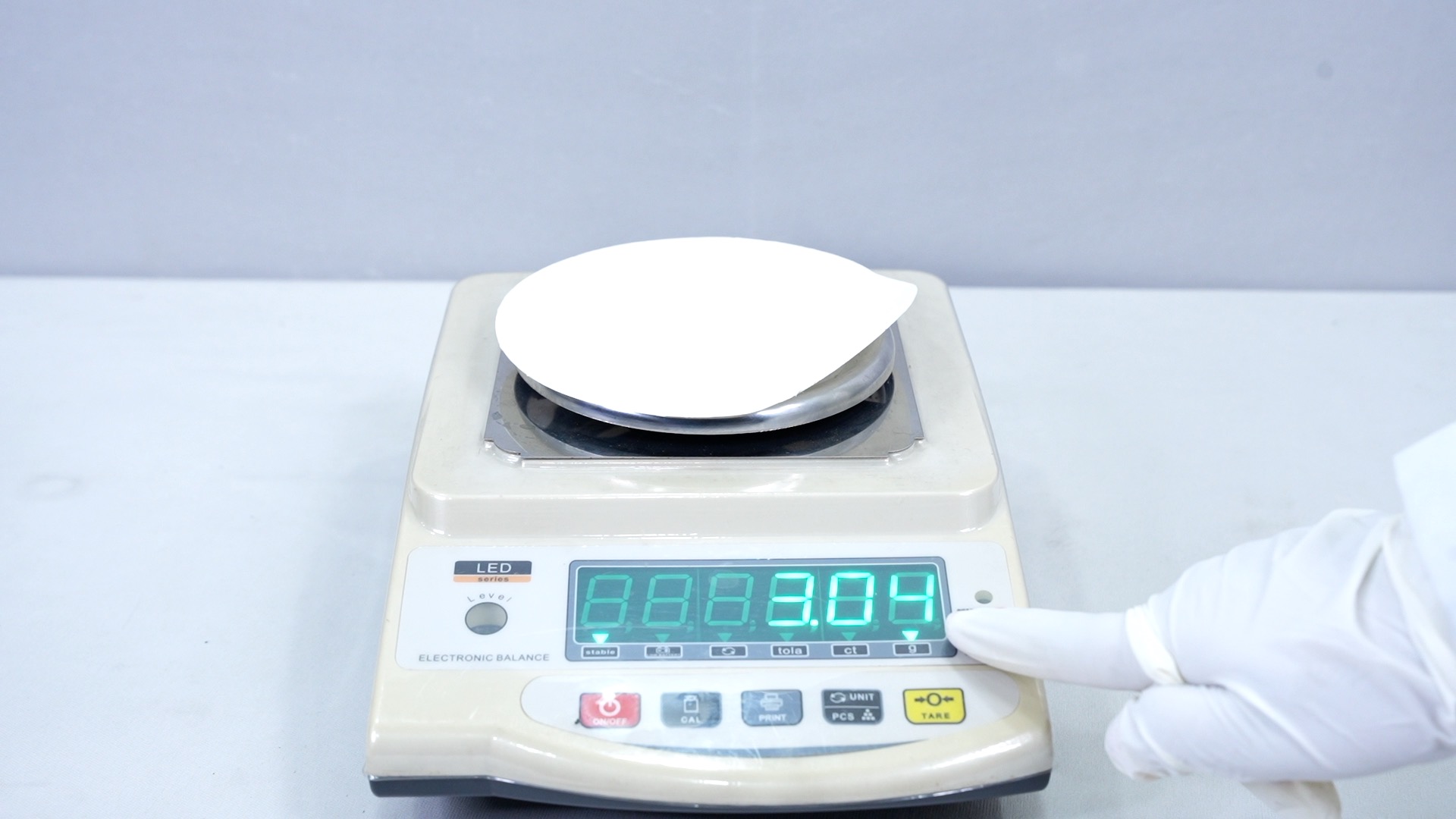

A test sample is exposed to the tester, with a known amount of water allowed to come into contact with the sample surface for a defined period of time, usually in the range of 60 s-10 min. The water is then removed at the end of that time and the sample weighed to see how much water has been taken up. Where the absorption is low, it will be more resistant to water, an indication that your packaging can take a deal of moisture.

So why is this test so crucial, one may wonder? Now, let's consider all possible wet scenarios: in case of humid or rainy weather, at the time of shipment, and even in case of spilling. Your packaging or your paper product itself might take up too much water and thus warp, weaken, and even destroy the contained substance. A high-quality, moisture-resistant material ensures your product is safe and presentable no matter the conditions.

Moreover, packaging materials applied within industries like food and pharmaceuticals have to comply with extremely strict standards so that moisture cannot affect the safety and quality of the precooked product. The Cobb Sizing Tester is a standardized and reliable method in achieving this for all materials under use purposes.

The Cobb Sizing Tester is a simple but precise equipment used in the measurement of the water absorption of paper, board, and other related materials. The major parts composing a Cobb Sizing Tester are as follows:

It is a metal or transparent cylinder that holds the amount of water to be immersed. Function: The cylinder is put on top of the sample and then filled with water in order to determine how much water the material can absorb.

Description: An apparatus to securely hold the sample during the test. Function: It keeps the sample immobile and flattened-the water will not leak under the sample, providing very accurate test results.

Definition: The flat area to hold the paper or board sample. Function: It is used to hold the support during the test and provides a good, flat area for the test to avoid any sort of distortion in the water-, tested-surface.

Definition: The material that absorbs excess amount of water from the sample after the test. Application: It quickly picks up the water from the surface of the specimen for measuring the water penetrating into the material.

Function: A pressure roller that applies equal pressure all over the specimen during drying. Operation: It ensures contact with uniform intimacy between the absorbent paper and the specimen and, therefore, the exclusion of free water.

Description: An accurate balance for weighing the sample prior to and after testing. Function: To measure the sample weight before water exposure and after blotting to determine the amount of water absorbed.

Description: An analogy or electronic timer Function: Measurement of the exact time period the sample is exposed to water to uniform the conditions

1. Does the Cobb Sizing Test apply to recycled paper products?

Yes, the test can be applied to recycled paper products for water resistance determination. However, absorption in recycled papers may be different compared to virgin paper.

2. What is the limitation of the Cobb Sizing Test?

Since the Cobb Sizing Test is focused on the absorption of surface water, it may be inappropriate for materials in which total water permeability, or long exposure to water, is a factor in application.

3. What does high Cobb value mean?

High values of Cobb imply that a high quantity of water has been absorbed by the material; thus, it may be less adequate for applications which require some resistance to water.

TIME TO UNLOCK YOUR POTENTIAL. ORDER OUR PRODUCTS NOW.

Contact us at +919210903903 or send your queries over mail at info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?