I want you to imagine that you are a manufacturer of sensitive electronics. You have spent hundreds of hours perfecting your product to ensure every element is immaculately put together. Now, the final touch: it's ready to go into distribution lines and be shipped off to customers all over the world. Here's the catch, it won't arrive in one piece if that packaging can't do its job.

This is one of the most popular nightmares of any manufacturer: crushed corners, damaged goods, and unsatisfied customers. A small defect in the structure of a box could translate into major financial losses, not to mention that it can also taint a business's reputation. How, then, will you be able to tell that your packaging is tough enough to handle the rigors of transport?

Enter the “Edge Crush Tester (ECT)” –– that unsung hero who can let you know whether your boxes can handle the heat or not!

This is a device used in the laboratory for determining the edgewise compressive strength of corrugated boxes. In simple words, it's a machine that will let you know how strong the edges of your cardboard boxes are. Why is this important? This is important because many times, the edges are the first parts that usually fail when under pressure.

Ever wondered why some boxes crush easily and others don't? It's pretty straightforward: edge crush strength. An ECT will give you an exact reading of that particular strength and let you know whether this or any other type of packaging is going to be protective enough for your product when it's shipped or moved around.

Let's break down the process:

STEP 1: Sample Preparation

A small piece of the corrugated board, usually the one with 3 to 5 ply, is cut from the box or material you are testing.

STEP 2: Placement in Tester

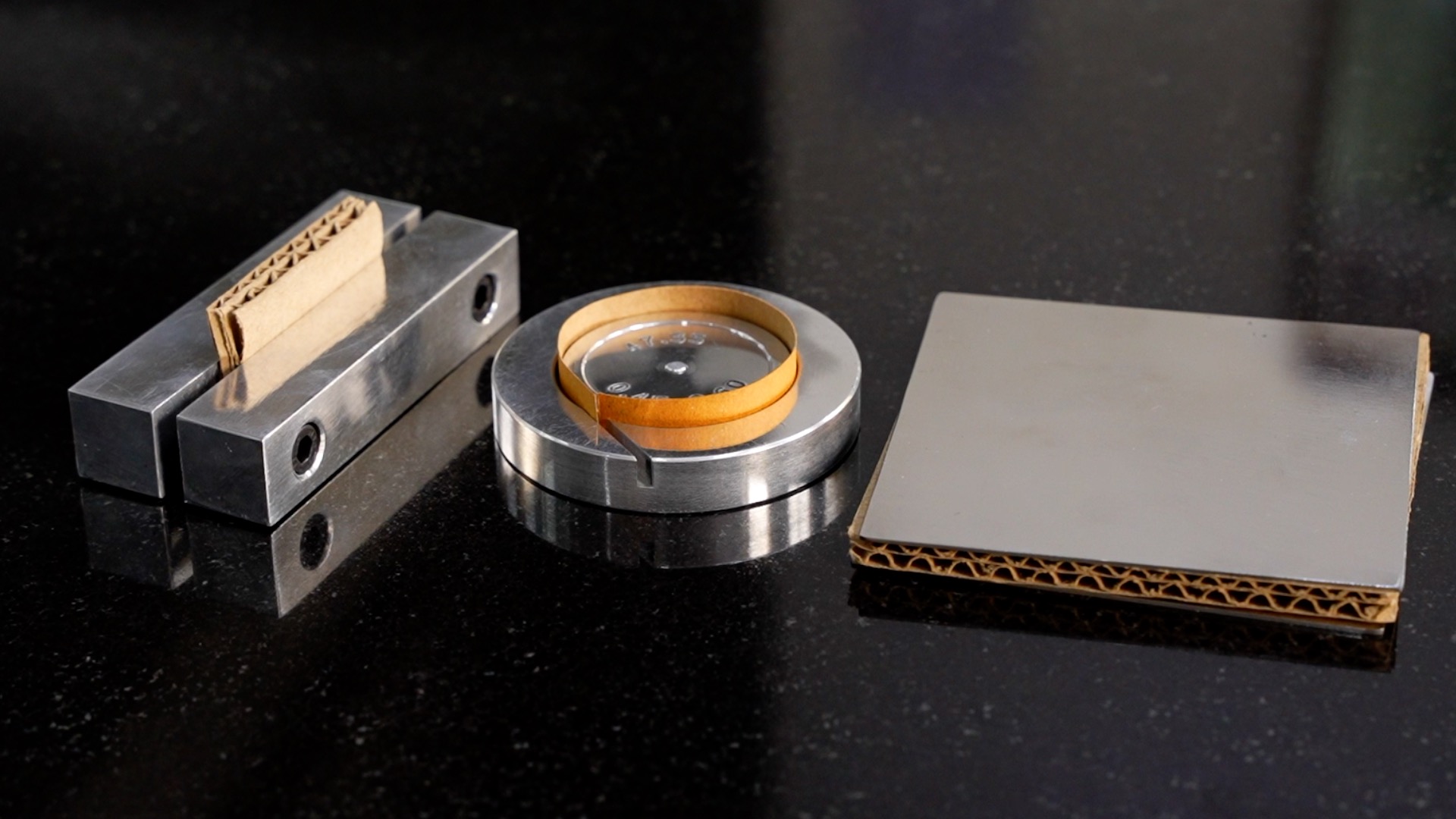

The test specimen is placed vertically between two compression plates in the Edge Crush Tester. The edges of the specimen are aligned, such that the applied force will be directly along the edge, simulating the pressure this box may encounter during stacking.

STEP 3: Applying the Force

The apparatus applies a compressive force to the sample, which is gradually increased until the specimen shows the first signs of buckling or collapse.

STEP 4: Measuring the Strength

The maximum force the sample can hold up to, without collapsing, is recorded. That value is your edge crush strength, usually expressed in pounds per inch or newtons per meter.

The results will show how strong the edges of your packaging material are. High strength, in most cases, will keep boxes from giving in to stacking or rough handling.

1. Display of Compression strength of test specimen by Microprocessor with accuracy

2. Separate fixtures for Ring crush, Edge crush, and Flat crush test

3. Highly accurate test results under a compression force

4. Strong clamps for proper gripping

5. Bright LED display

6. Inbuilt calibration facility

7. Feather touch controls

8. RCT/FCT/Edge Crush Tester reveals the crushing resistance in terms of Kg/Unit length.

1. In what way is the Edge Crush Test different from the Box Compression Test?

The Edge Crush Test specifically calculates the strength the edges of the corrugated board hold, whereas the Box Compression Test measures the overall compressive strength of the entire box. Both tests look at different factors in packaging strength.

2. In what type of industries is the Edge Crush Tester used?

The Edge Crush Tester is used widely in the packaging industry, e-commerce, retail, foods and beverages, pharmaceuticals, and any industry that is extensively dependent on corrugated boxes for shipment and storage.

3. In what way can the results of the Edge Crush Test be determined?

A higher ECT value will mean that the edges are able to withstand heavier loads or rougher handling of the box. Lower ECT values carry the opposite message, implying that the ability of the edges to withstand loads may lessen even to the extent of insufficiency for some given conditions of shipping.

Contact us at +919210903903 or send your queries over mail at info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?