The bottles are one of the most trusted sources for packaging fluid materials by manufacturers from the packaging & beverage industry. These bottles are required to have a certain level of seal integrity and an optimum wall thickness for perfect packaging of the fluid inside. The accurate wall thickness not only ensures safety but also provides a cushion to save money for the manufacturer.

For instance, a manufacturer uses thicker walls than required so that will end up consuming more plastic material than necessary. This kind of situation on a large scale can lead to huge unknown losses.

This is the reason that makes it mandatory for the manufacturers to test the thickness of the walls of the bottle before their dispatch for delivery to the end consumer for utilization.

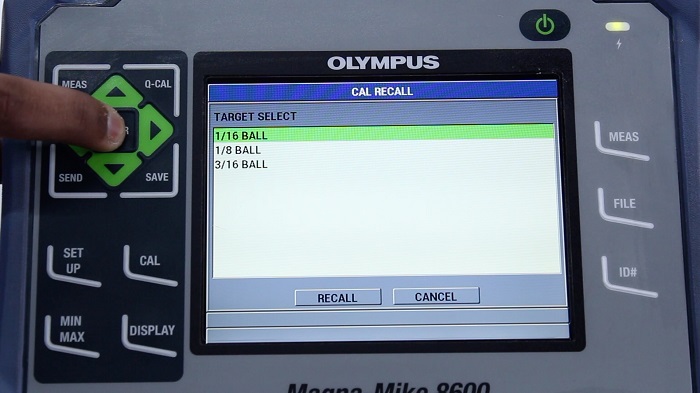

This urged the Presto Group to come up with an amazing solution to help manufacturers assess the wall thickness, called the Magnamike 8600 wall thickness gauge.

The instrument is a result of high-class engineering which made it possible to identify the thickness of the walls of a container or bottle. The instrument functions on a Hall Effect technology basis due to the magnetic assembly of the instrument.

Let us dive deeper into the functioning of the instrument which will help us get a better understanding of the Magnamike 8600 wall thickness gauge.

The instrument follows the Hall Effect technology due to a very simplistic magnetic procedure to complete the test. The instrument is widely used to determine the wall thickness of non-ferrous materials like plastics, glass, aluminum-enclosed sheets, etc.

The instrument is offered with a magnetic sphere that is used with the help of a magnetic probe. The magnetic probe is offered in two different variants which are:

Both these probes are used widely by manufacturers depending upon the material they perform testing on.

The magnetic sphere or magnetic ball is placed on the inside of the wall. For ex. In the case of a bottle’s wall thickness test, the magnetic sphere will be dropped inside the bottle from the opening.

The magnetic probe is turned on which activates the magnet’s electromagnetic field. The magnetic probe is positioned next to the wall of the specimen from the outside and due to the charged electromagnetic field across the magnetic tip of the probe, it attracts the magnetic sphere or ball from the inside of the ball.

Both the magnetic probe and magnetic ball run across each other on either end of the ball. The magnetic probe is attached to the wall thickness gauge for bottles that determines the distance between the tips of the magnetic probe to the closest point of the magnetic sphere.

Since the magnetic probe & ball are separated from each other through the layering of the wall, the distance indicated on the screen is the thickness of the wall.

The operator can now simply record the results indicated on the LCD display of the instrument and analyze these results for future comparison purposes.

The instrument is equipped with numerous quality attributes that promote the single-handed working of the wall thickness gauge.

The instrument is equipped with high-end features that allow the operator to perform testing with minimal hassle and minimal issues.

The most prominent feature of the instrument is its portable built which allows the manufacturer or the operator to perform testing anywhere in a really quick time. The portability of the device without any compromises in the accuracy has gained the trust of manufacturers all across industries.

The instrument is equipped with a top-quality LCD screen that indicates the results of testing and allows the operator to profile the specimen. The screen has a VGA finish for premium-quality usage and a 60 Hz refresh rate which makes the testing process absolutely quick & facile.

The instrument is equipped with safety features as well that ensure accuracy-driven and hassle-free tests. One such safety feature is the incorporation of high & low-thickness level alarms.

The instrument also offers two variable magnetic probes for different materials. This satisfies the operator by ensuring controlled testing measures due to the accuracy-driven approach by the manufacturer of the instrument.

The wall thickness measurement results can also be read into different languages to enhance the ease of testing in different parts of the world and aid operators in keeping an accurate track of attained results in their own familiar language.

All these features incorporated within the instrument increase the trust of manufacturers from all across the world in this top-notch wall thickness measurement gauge.

Do not miss out on the top-notch lab testing instrument and achieve high accuracy in determining the thickness of walls of various specimens from different industries.

To place an order right away, you can reach out to our website and book an order with absolute ease. For further questions, feel free to call us on +91 9210903903. We would highly appreciate your feedback & act upon it on our e-mail info@prestogroup.com.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?