Perforations are a minor element that many people overlook in their daily lives, yet they are useful to bring ease and convenience. Perforations are tiny holes or rows of holes punched into a material (often found on paper, plastics, and packaging materials) that allow a portion of it to be easily pulled off. A perforation is used to make the material easier to rip or bend. Testing the perforations in the packets is essential to make sure that the packet will not get easily separated. Thus, you can easily test the perforations of the packaging materials with the help of the Presto perforation tester.

This lab testing equipment is useful in measuring the elongation and tensile strength of thermoplastic films used in packaging. During the perforation test, you can easily measure the force which will be required to separate the film from the place of perforation. Here in this blog, we are going to discuss the information about perforation and how you can easily test the perforation in the packaging. So, let us get started!

Perforation is the technique of putting tiny holes in the packing of two objects so that they may be readily separated. A Presto perforation tester measures the amount of force needed to separate two unique packets from a perforated region. This is excellent testing equipment is used for determining the strength of holes used on various packaging materials. The main motive for using this testing equipment is to test the force that can separate the products from the perforated area.

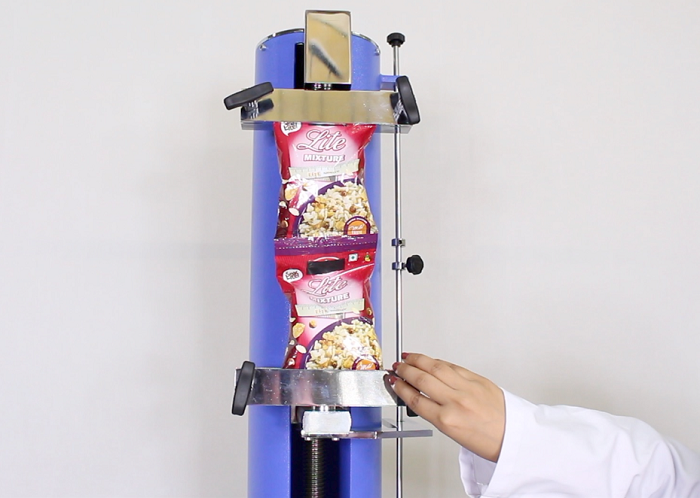

This lab testing equipment will be used to separate the products from the perforated area and examine the elongation strength or force of thermoplastic films. This will be used to separate the perforation film and the small sample will be used to carry out the test with the help of this testing machine.

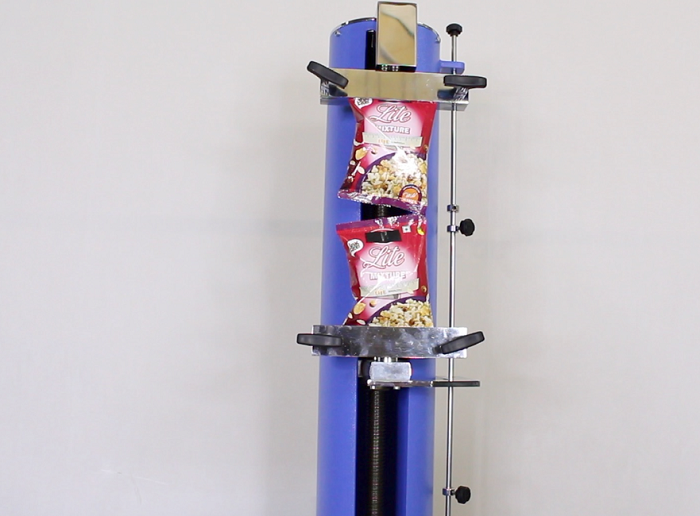

It comes with a limit switch that will serve as a safety element for the machine and helps to restrict the movement of the grips. Their outer body will be made of mild steel which will be duly powder coated. Below we have listed the perforation tester features and technical specifications.

The main purpose of the perforation test is to ensure that your specimen can be easily ripped or bent. Thus, you will be able to determine the elongation force and strength of thermoplastic films that can be extended using this test procedure. Below we have listed the features of the Presto perforation testing instrument.

With these features and technical specifications, it will be easy for you to conduct the perforation test. To conduct this test easily, you can follow the steps mentioned below.

The perforation tester from Presto plays a crucial role in testing the elongation strength of thermoplastic films which will be required in separating the films easily. Aside from the perforation films, an elongation is calculated using the stress-strain curve generated by this testing equipment.

The perforation test findings are then compared to those of a traditional tensile test. Below we have listed the steps to conduct the perforation test using this lab testing instrument.

If you need any further information about perforation tester price or discounts then you can give us a call at +91-9210903903 or email us at info@prestogroup.com. Our team of technical experts will easily consult with you regarding all your queries.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?