The transportation of products from one place to another has gone a notch higher with the sales & logistics businesses getting involved in the industry. The operators have the responsibility to transport the product & item safely from one place to another. However, the task is not as easy as it appears because the transit measures can be a major hassle for both operators and manufacturers.

The operators of the task use corrugated boxes as their prime source of packaging perishable as well as sensitive products. These corrugated boxes have been the first priority when it comes to packaging due to their affordability, ease of use as well as durability to a certain extent.

Although these corrugated boxes are constructed with adherence to the transit hassles there are still incidences where the corrugated boxes get damaged due to free falls by the labor handling the boxes.

This is the reason that testing measures before the boxes are utilized in the final process is so crucial. To make sure that these boxes do not get damaged due to the vertical impact they experience by free falling, the Presto Group offers a top-notch lab testing instrument called the drop tester.

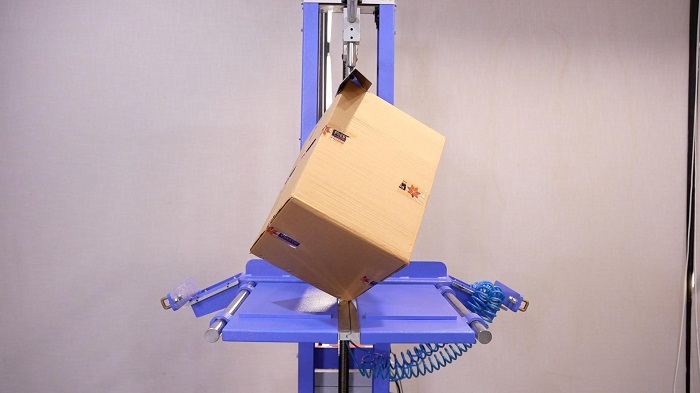

The drop tester is a lab testing equipment constructed with absolute precision to simulate the free falls that these corrugated boxes undergo during storage or transportation.

Let us take a look at how the lab testing instrument functions and aids the operator in reaching highly accurate results over & over again.

The instrument is designed with high-quality ergonomics to ensure a seamless functioning process and enhance the quality of corrugated boxes in the case of uncertainties driven by the conduction of the test.

The drop tester conducts the drop tests into three different methodologies for precise results. The three different methodologies are:

To conduct the flat drop testing, the operator simply clamps the dual-door platform and places the specimen on top of the platform. It is highly important to place the specimen as per the guidelines for accurate results.

In this testing measure, the specimen is placed with the flat end facing the platform. The operator then opens the dual door specimen with the help of the pneumatic pedal. The opening of the platform results in the free-falling of the corrugated box.

The operator can now simply assess the damage that took place due to the vertical impact of the free-fall.

The operator can also adjust the height of the platform from which the specimen fell. This enables the operator to identify the vertical impact resistance of the specimen from different heights.

Similarly, in the edge drop testing, the corrugated box is placed on top of the dual-door platform but this time, the specimen is adjusted with the help of a specimen position holder associated with the bar of the drop testing machine. The specimen is placed in such a way that its edge faces the platform.

This positioning of the specimen results in the impact directly on the edge of the specimen and determines the impact resistance of the edge.

In the corner drop testing, the specimen is positioned with the corner end facing the platform with the help of the specimen holder and thus the specimen faces the impact on its corner when dropped from the platform.

The operator can easily assess the uncertainties caused due to the falling of corrugated boxes from different angles and at variable heights. This is how the drop testing machine functions and aids the operator achieve high levels of precision during the course of the production process.

The lab testing equipment possesses some high-end attributes that are crucial for the smooth & hassle-free functioning of the device.

The drop testing equipment is constructed as a top-quality lab testing instrument that is enriched with quality features that ensure seamless testing with absolute facile and enhance the accuracy levels a notch higher.

The most prominent feature of the lab testing instrument is the motorized dual-door platform of the drop tester. The motorized function allows the operator to perform the drop test from different heights and satisfy different standard guidelines. The dual door feature of the equipment ensures that there are no external forces applied other than gravity during the conduction of the drop test. The platform also has a rugged surface that provides no slippage guarantee of the specimen.

The lab testing equipment is offered with a pneumatic pedal that eradicates the scope of human error as the human effort is minimized.

The instrument is offered with a precise specimen holder that allows the operator to conduct the test with 3 different methodologies i.e. the flat drop test, the edge drop test, and the corner drop test. The three methodologies ensure accuracy and enable the operator to eradicate uncertainties (if any) assessed due to the free-fall from different angles & heights.

The drop testing equipment has encouraged manufacturers from the rigid paper & packaging industry to get their hands on it due to its robust construction with mild steel material that is coated with 7-layered powder paint. The instrument’s construction ensures the longevity and durability of the machine from corrosion as well as rusting.

The drop testing equipment is the finest simulator of free falls from different elevations & angles that a manufacturer can get their hands on. To know more about the lab testing instrument, feel free to get your questions answered on our website. You can also reach out to us via phone call to place the order for the drop tester at +91 9210903903. You can also write to us on our e-mail with your queries & feedback at info@prestogroup.com.

The Presto Group would love to serve you with the highest quality of lab testing instruments right away.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?