In the packaging industry, testing the accuracy and durability of packaging products is an important aspect of quality control. From evaluating the impact resistance of materials against compression forces to assessing the performance of corrugated boards against bursting, there are several factors that need to be taken care of. Thus, with Presto's high-quality paper and packaging testing instruments, manufacturers can easily conduct accurate packaging tests and deliver quality products to customers.

We offer a wide range of paper and package testing equipment that will help to maintain the integrity of products effectively against external factors. Furthermore, our corrugated box testing machines made as per industrial standards will help the manufacturers to achieve accurate testing results. In this blog, we will discuss a brief about Presto's top 5 paper and package testing instruments that will used for accurate packaging.

In this fast-paced world of manufacturing and production, ensuring the reliability and accuracy of paper and packaging products is important to ensure that accurate products will be delivered to the customers. This is where paper and packaging testing instruments come in. You can easily design high-quality packaging products with Presto high-quality paper and packaging testing instruments.

Below we have listed the top 5 paper and packaging testing instruments that will help you to detect the flaws present in the packages accurately.

Box Compression Tester - Digital: This is one of the high-quality paper and packaging testing instruments that will be used to test the compression strength of corrugated boxes when the compression force is applied to them. The digital compression tester has been designed with user-friendly controls that are easy to operate. Testing the compression strength of boxes will help the manufacturers in ensuring their integrity by placing the specimen between the compression plates.

This testing instrument has been made with advanced features to make it easy for manufacturers to conduct compression tests on the materials.

Bursting Strength Tester - 2.0: This is another testing instrument that should be used in the packaging industry to test the burst strength of boxes. You can test different sets of products using this quality testing equipment which includes corrugated boxes, fiberboards, uneven boards and boxes. This new model of burst testing machine comes with an advanced feature of automatic burst factor calculation. It comes with robust gripping clamps and a grooved structure to prevent the slipping of the specimen from the testing area.

Edge Crush Tester (ECT): The digital edge crush tester is considered to be one of the sophisticated lab testing instruments that measures the edge crush value of the material with precision and accuracy. This high-quality testing equipment comes with a microprocessor-based display and separate fixtures to ensure that the manufacturers can conduct different types of lab tests including ring crush, edge crush, and flat crush test. With its feather touch controls and easy-to-operate features, manufacturers can operate this testing machine with precision and reliability. You can also view the computerized model of the edge crush tester through which you can easily generate lab test reports.

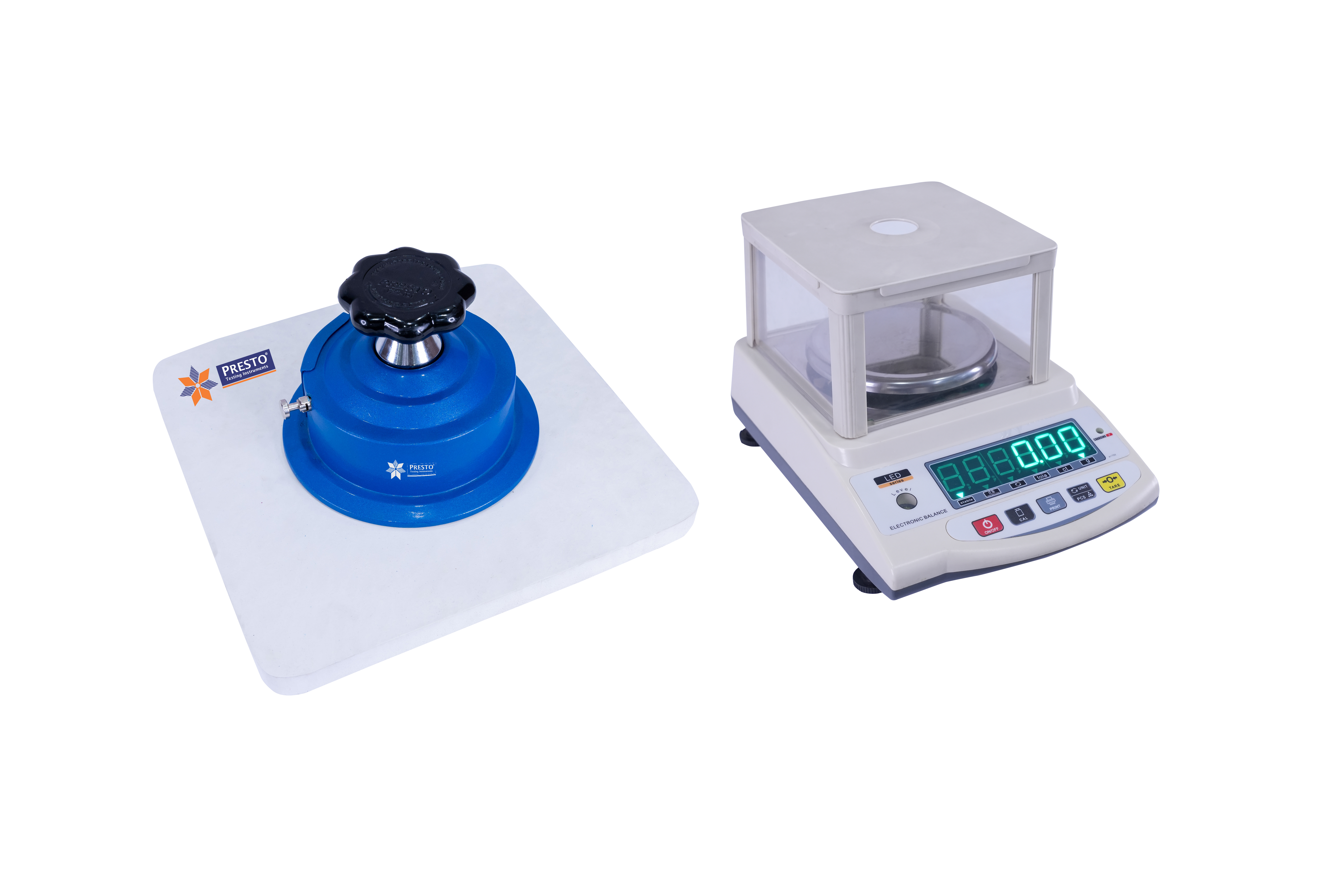

Grammage Checking kit: Grammage is considered to be one of the major aspects of quality control that will help manufacturers in testing the grammage of materials to determine its strength. This grammage checking kit comes with a GSM round cutter and GSM weighing balance that makes it easy for the manufacturers to conduct quality tests on the materials.

This round cutter for grammage checking comes with a disc area of 100 cm2. Once the specimen is placed on this weighing balance machine, the grammage of the material will be evaluated. The round cutter for GSM has an aluminium die-cast main body and heavy-duty German blades. This makes it easy for the manufacturers to cut the samples.

Digital GSM Balance:

Drop Tester: This is one of the widely used lab testing instruments in the packaging industry. This lab testing equipment stimulates the scenario in which packages will be dropped from a certain height. It provides valuable insights into how well your packaging holds up under real-world conditions.

You can also use a drop tester pneumatic model that will make it easy for the manufacturers to conduct a quality test on the materials. By conducting drop tests using this specialized equipment, companies can gain valuable insights into how well their packaging holds up under different conditions. They can then refine their designs accordingly, ensuring optimal product protection throughout the supply chain.

With these top 5 lab testing instruments, manufacturers can get accurate lab testing results. If you want more information about the use of these quality testing equipment then you can give us a call at +91-9210 903 903 or email us at info@prestogroup.com. Our team of technical experts will consult you regarding all your needs and queries.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?