Just imagine, a consumer buys some product online—a new device or food supplement—he or she has been looking for, for weeks. The product arrives and, out of the excited mess, the consumer digs up a disastrous find. A damaged product! The product that absorbed moisture, the packaging let a fragile item break. The customer gets furious and boom! You lost a customer. It goes right into the heart of what makes your brand good.

Maintaining package integrity is of utmost importance in industries like pharmaceuticals, food, electronics, etc. But how do we make certain that each package remains airtight, safe, and secure?

How can minor leakages, in fact, lead to contamination, spoilage, or the failure of a product, particularly in industries that demand nothing but good quality and product safety? All of those are potentially serious safety risks, incurring costly product recalls, not to mention customer dissatisfaction. Even though a package can be carefully examined visually, this will not reveal micro-leaks. But what you want is a high-precision, reliable way to test the integrity of your package--one that gives you the assurance to put your worries about your brand's reputation to rest. Well, say hello to the Vacuum Leak Tester!

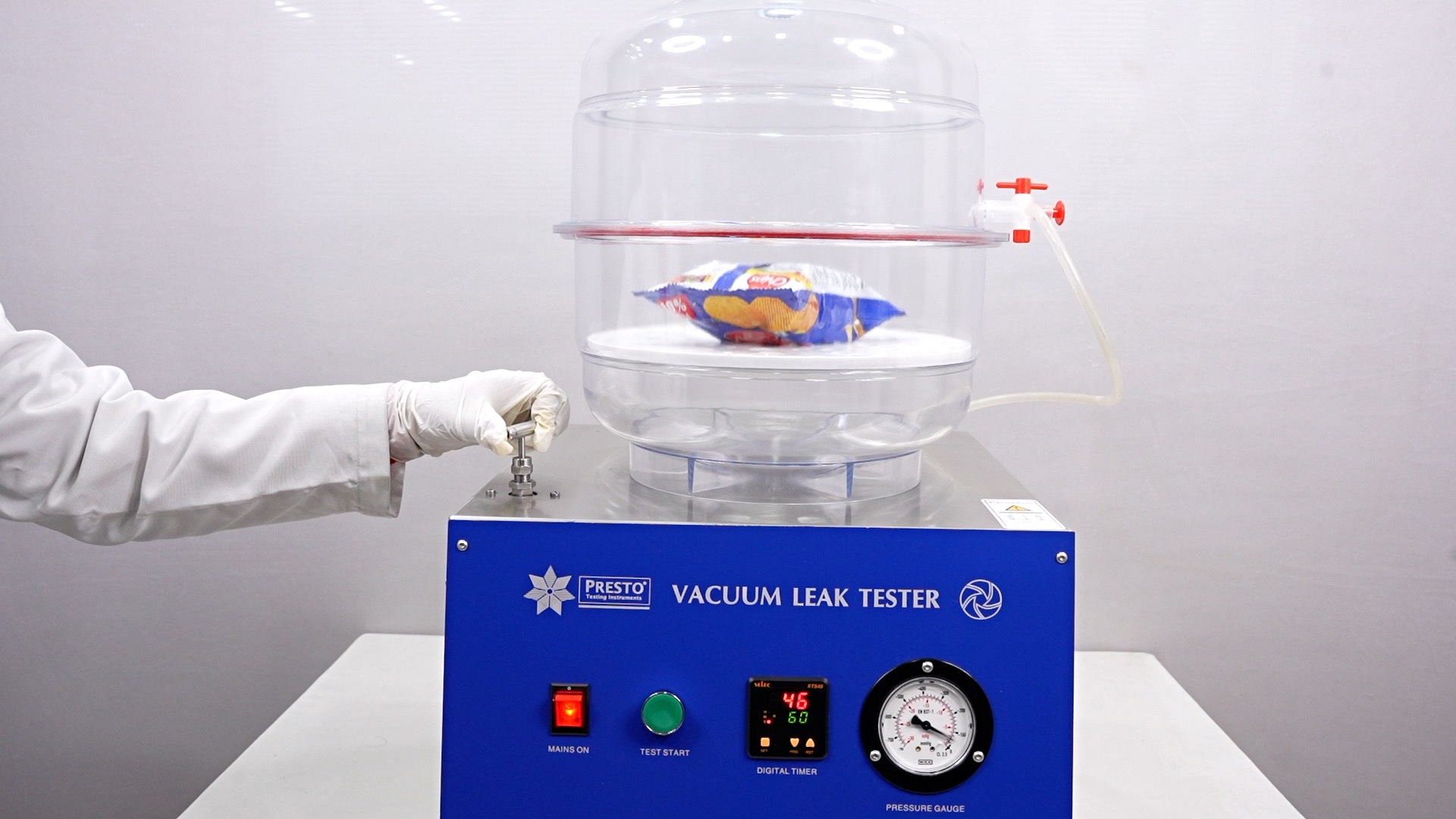

This machine is indeed one of the biggest eye-openers for the industries, that rely on the perfect sealing of their package. This instrument is specifically designed, to ensure leak detection within sealed packages, to guarantee full airtightness. Small leaks can be identified using quick, efficient, dependable, and accurate methods for testing in blister packs, pouches, sachets, bottles, or containers.

So, what is it that makes this tool so indispensable? Find out the components of a Vacuum Leak Tester, its components, and why it should be part and parcel of your quality control process.

To understand the workings of this amazing equipment, you first have to become familiar with the most important elements. Let's see how each key element contributes to detecting even the tiniest leaks.

First on the list is the vacuum chamber—the “heart” of the Vacuum Leak Tester. This is where all the magic happens. The chamber is designed to hold any package intended for testing. Normally, most of it is transparent material like acrylic or glass, so the process of testing can be observed from outside. The chamber is very important by itself because it builds up a created vacuum that changes the pressure, and hence helps to detect a leak, if present.

It pumps the air out of the chamber and drops the pressure to the levels that the product may experience during transport or storage. Here again, it is the pump that creates a controlled, and consistent vacuum level for good leak detection.

The pressure sensor is the user's eyes and ears for the duration of the test cycle. It continuously monitors changes during the test cycle, within the vacuum chamber, and provides real-time data with respect to any fluctuation.

The control unit may, however, be said to be the brain of the operation. In the sense that the test parameters, such as desired vacuum level and time, are actually set up there. Control units take in data from a pressure sensor, process the acquired data, and control the operation of the vacuum pump.

A good sealing mechanism keeps the test vacuum chamber airtight. This device keeps a vacuum in the chamber so it will not leak out.

The display and interface provide the readings, test results, warnings, and errors. User interfaces, most of the time, have touchscreen interfaces and an easy-to-use menu. This makes it easy for one to utilize the tester. It provides a fast analysis of results for instant corrections of deviations.

The test results and performance history are automatically captured, and analysis can be done to give analytical insight into your quality packaging. They help in problem finding, and maintaining consistency during testing.

Finally, the sample holder or fixture is designed to locate your package firmly in a vacuum chamber, ensuring it does not overturn when testing, and that all spots of the vacuum are equal on your packaging. In some fixtures, one can adjust to accommodate a different size and shape of a package.

The package to be tested should be put in a vacuum chamber. This chamber is usually constructed from see-through material so that the operator can see the testing process.

After the package is placed, the chamber is sealed and air from inside is removed, so that vacuum is created inside the chamber. That simulates the conditions that the package might face during transport or storage.

After the application of the vacuum, the package is again monitored by a tester for any indication at all, that air is escaping from inside—bubbles, deformation, or other visible signs that the integrity of the seal has been broken.

If there is a leak present, the decreased pressure within the chamber will permit the package to enlarge, and air or liquid will flow from the site where the leak was present. The tester would sense this event taking place, and then signal the operator accordingly.

The package placed after the testing process is analyzed. If there are no leaks, then it simply deems to be fit. If the leak has been detected, the package has to be said to fail, and then just corrective measures have to be taken.

The overall process is very fast, involving just a few minutes on average, so it is suitable for batch testing or spot checks in a production line.

It can check a wide variety of materials such as bottles, cans, sachets, etc, made of various materials, such as plastics, glasses, and metals.

Although this is primarily a tool for packaging, there are other applications where this detector will be handy, including sealed electronic components and some medical devices.

Proper instructions must be followed, protective gear should be worn, and the chamber must be tightly closed.

Contact us at +9199210903903 or send your queries over mail at info@prestogroup.com

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?