Moisture is an undisciplined humidity level that causes degradation, loss of structural integrity, and even complete destruction of the product. Such damage can cause immense financial losses to industries such as electronics, pharmaceuticals, food packaging, and textiles, among others. Proper moisture control means not just a requirement, but also a promise in terms of trademark, brand identity, and product reliability.

One of the most potent tools in this moisture control space is the Humidity Chamber. With specialized equipment designed to mimic a vast array of humidification and temperature variations, companies can have their products evaluated in real-world conditions to ensure every product meets rigorous specifications on quality.

It is also referred to as a humidity chamber and is essentially a climatic or environmental chamber. It's a testing instrument where temperature and humidity are tightly controlled within an enclosed space. Thus, it's designed to create specific environmental conditions to test the reaction and performance of a product under different levels of humidity.

Whether simulating tropical humidity, arid conditions, or even rapid fluctuations between the two, it provides a critical tool in predicting how the product will stand up to different climates over time. The predictive tests even help manufacturers identify weaknesses in their products so that improvements can be made before reaching the customer.

Humidity chambers are specifically used in industries like electronics, pharmaceuticals, automotive, textiles, and food packaging wherein quality products need to be verified for their performance under controlled conditions of the environment.

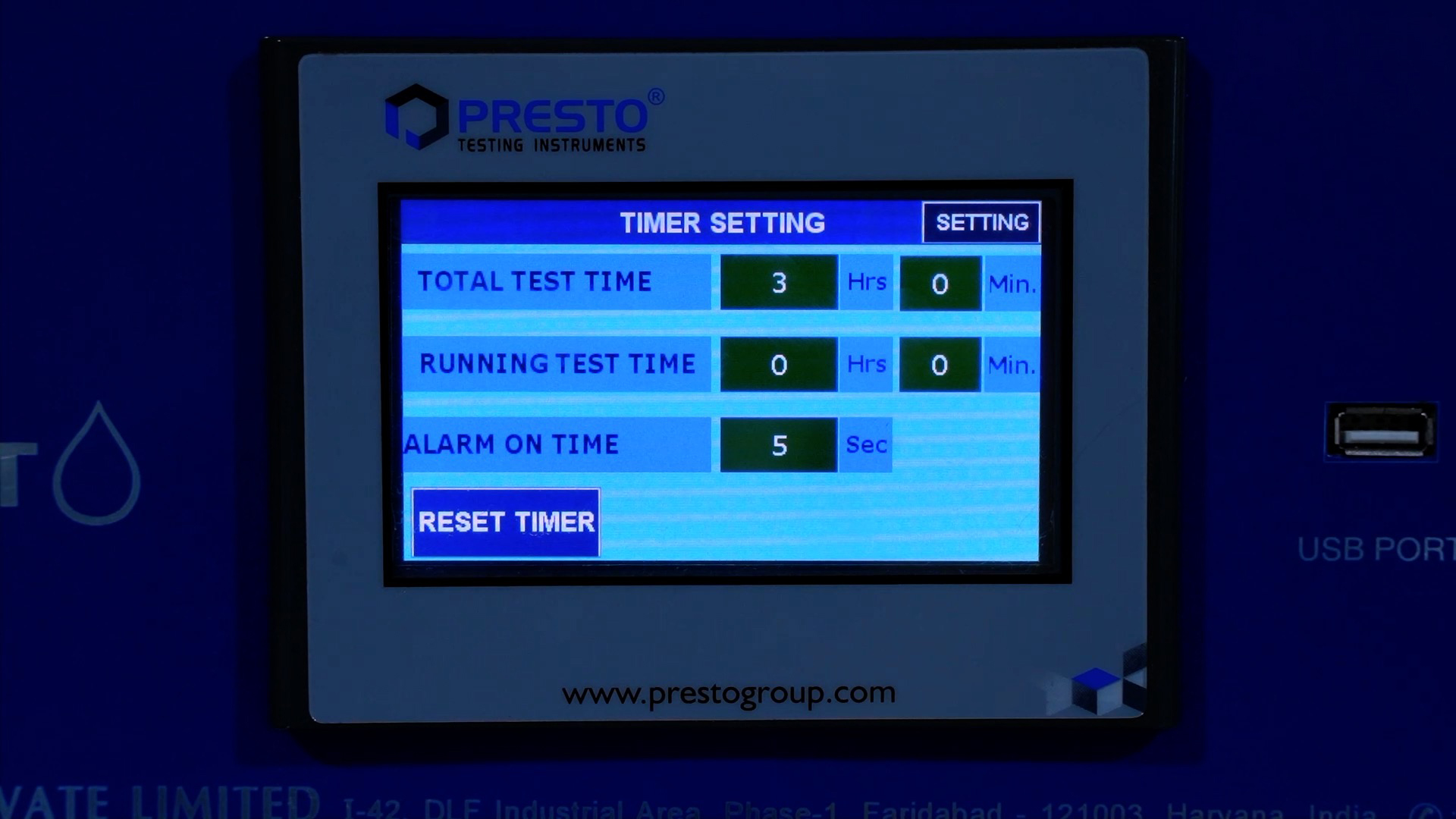

In the context of reliability testing equipment, Presto stands tallest in the industry. With more than 40 years of experience in developing and manufacturing precision testing equipment, Presto has emerged as the partner of choice for most industries for quality assurance.

Appropriately priced by Presto's testing solution, it has found acceptance in various leading brands such as Britannia, Flipkart, Amazon, Harley Davidson, Coca-Cola, and Pepsi, among many more. It all comes down to the fact that Presto is a brand guaranteeing quality, precision, and customer satisfaction at its best.

At Presto, the humidity chambers are made over a foundation of deep understanding of each industry-specific requirement. Presto's engineering traditions ensure that all of its products are sustainable and truly deliver precisions with the least environmental damage. With top-edge technology and a very high level of quality check, accompanied by industry expertise, Presto's humidity chamber offers unmatched performance, durability, and reliability.

A humidity chamber is absolutely indispensable for manufacturers who want to achieve quality control and assurance, especially when the product is going to be exposed to environmental changes. Here's why the control of moisture is important:

A humidity chamber actually operates on the principle of offering a controlled atmosphere in which temperature and humidity can be set at specific levels. Here is a brief look at its key components:

Humidity testing is very important in predicting the performance of a product when used in variable environmental conditions. It prevents moisture-related potential problems, such as corrosion, deformation, or degradation, so that the product will be reliable for the end user.

Yes, a high-quality humidity chamber can support a wide range of humidity levels, from dry settings to wet surfaces, and hence enables manufacturers to test the strength and strength of products under different conditions.

Electronic, pharmaceutical, automobile, textiles, and food packaging industries require the facilities of a humidity chamber to a great extent since these industries demand strict control over performance under environmental stress.

Contact us:

Phone: +919210903903

Email: info@prestogroup.com

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?