Imagine yourself in a scenario where your brand-new product sits on the shelf, looking bright and catching in its shiny and attractive packaging. It is the kind of packaging that makes someone want to reach out and grasp it, taking it home. But as your hand slides across the surface, the unexpected happens - a subtle scuff mark appears. It is a small imperfection, but in the world of packaging, where the look is everything, this little flaw equates to disaster.

Scratches, scuff marks, and abrasions might be trifles to many, but they actually detract so much from the appeal a product has, most especially to industries that bank on cosmetics, electronics, and luxury. Can you imagine buying a high-end phone or, worse, a luxury watch where the box outside looks as if it has undergone wear and tear even before it does when you open it? Definitely not the first impression you had in mind, huh?

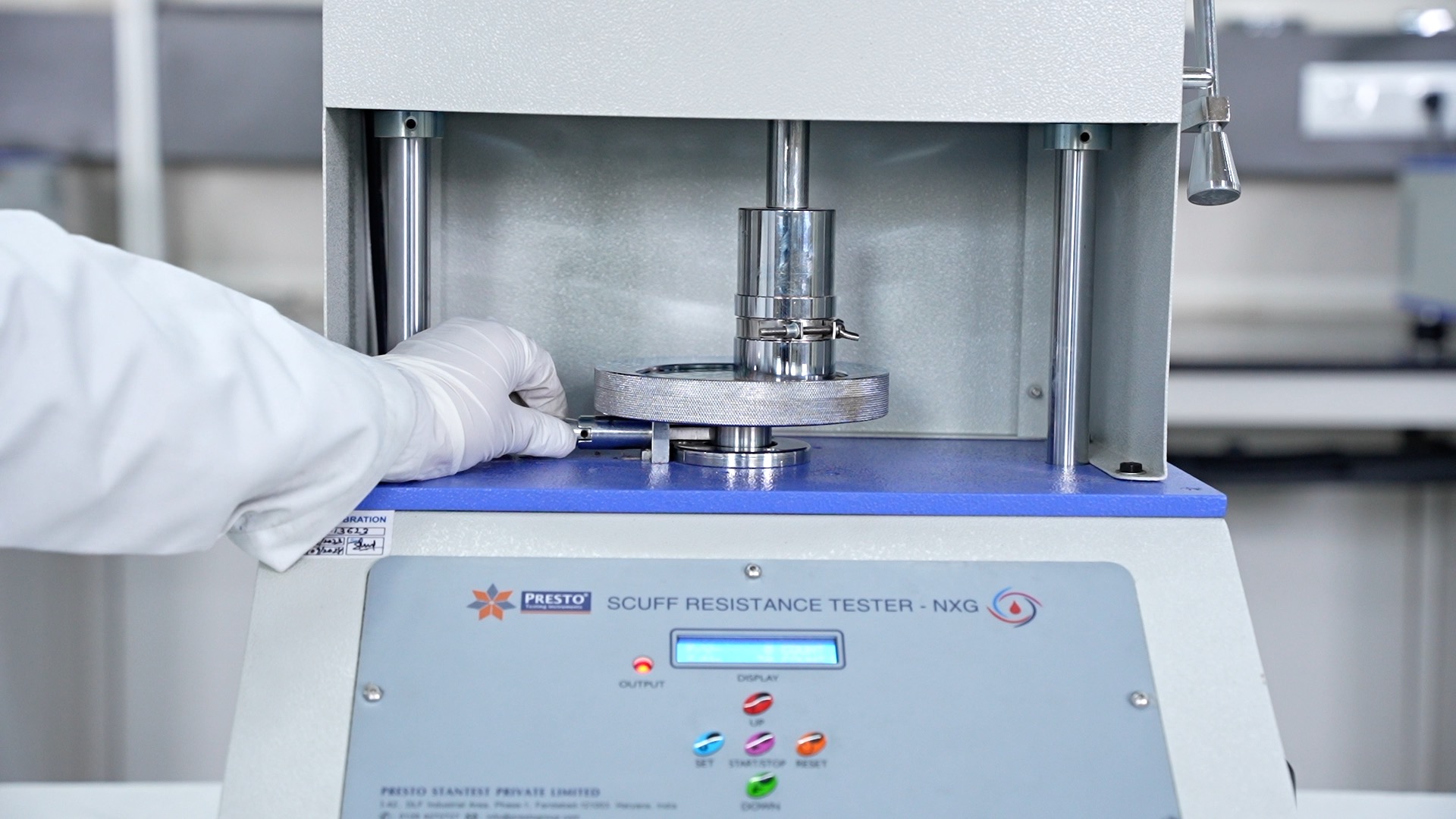

Here comes the role of the Scuff Resistance Tester. This unsung hero comes along, joining the forces of war against wear and tear in packaging. Let's go a step further to see exactly how this important tool works and why it is such a game-changer where quality control in packaging is concerned.

The Scuff Resistance Tester is an apparatus that can simulate the wear and tear packaging materials may go through after shipment, handling, or shelf life. It measures the resistance of printed material labels, cartons, or packaging to scuffing, scratching, and rubbing. This is to ascertain that a product maintains its appearance even against rough handling, thus preserving aesthetic appeal and, of course, market value.

You might wonder, "Why go to all this trouble for a little scuff mark?" The answer lies in consumer perception and brand integrity. If the packaging looks damaged or worn out, this may affect consumer attitude towards the product inside. For premium brands, even minor imperfections result in huge losses in sales and brand reputation.

Scuff resistance testing helps manufacturers maintain quality, reduce returns, and enhance the brand image by making sure that it withstands all phases of shipment, handling, and storage without losing its visual appeal. This helps in reducing the chances of returns of products due to damaged packaging, an experience that can be costly and time-consuming. Protect the image of the brand by delivering products in pristine packaging that shows the quality of what is inside.

Scuff resistance will maintain the appearance of the packaging throughout its shelf life, reducing the risk of damage leading to a shortening of the shelf life.

The scuff resistance tester works at the pressure of 2 psi. However, two other variations can be provided according to the customer’s requirements, which are 1 psi and 4 psi.

Yes, there are two differently-sized clampers installed in the scuff resistance tester. The clamplers must be differently sized to maintain the proper friction and smooth testing process.

Three different models are available for scuff resistance testers, namely:

Basically, the tester uses two surfaces: a stationary one and a moving one. The sample is placed on the stationary surface while the moving surface scuffs or abrades it under controlled conditions. The degree of scuffing is subsequently assessed to determine resistance.

The Scuff Resistance Tester is an integrated test model that can perform tests on a wide range of materials, from papers to cardboard, labels, plastics, and printed materials used in packaging.

Contact us at +919210903903 or send your queries over mail at info@prestogroup.com

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?